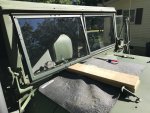

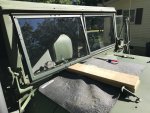

Fellas the new windows are in. As with all things Deuce a bit of drama was involved. I can't tell you how long it took me, because to do so would instantaneously invalidate my manhood. My first order of business was to make sure that my face, iphone, best bluejeans, and any freshly painted OD green surfaces were smeared with anti-seize. The itsy-bitsy hinge screws went in very easily. I used some wood to substitute for " Soldier B " to hold the window up high enough so I could engage the little hinge screws. The new latches hit the little stationary holder doohickeys by an 1/8", so I had to re-profile the doohickeys with my grinder and a file. It's comforting to know that all of the familiar Deuce air gaps are still there. After all, how else would the wasps get in! Now I'm wondering how I'm going to dispose of the aircraft carrier sized box they

came in.

came in.

came in.

came in.