davidb56

Well-known member

- 1,020

- 1,238

- 113

- Location

- Bonners Ferry Idaho

I need to replace some top cover parts such as the shifting forks, and shift plate. Im having trouble finding them at the usual places. any leads?

Steel Soldiers now has a few new forums, read more about it at: New Munitions Forums!

Is that lid complete with the forks?

M35-111 | Transmission Shifter Lid Spicer 3052 / 3053A

Transmission lid for Spicer 3052 & 3053A Fits M35A2 Series - 2 1/2 Ton

NSN #: 2520-00-347-4591

Part #: 7521056

Price: $125.00

M35-227 | Shifter Lid Gasket Spicer 3053 / 3052 Transmission Lid Gasket

Transmission Lid gasket- Spicer 3053 / 3052 Fits M35A2 Series - 2 1/2 Ton

NSN #: 5330-00-752-1061

Part #: 7521061

Price: $45.00

I PM'd him. he has been very helpful. I didn't know how to attach this pic to a pm, so I told him I'd post it here, so he can reply. Im not sure if the right side "lug" is supposed to match the left side. But the transmission got stuck between gears by itself. engine off, shifter in a gear, parking brake engaged on wooded mountain terrain. So Ive contacted him because, he's a expert on them. IMHO.Yeah I see some rounding, but doesn't look bad to me. Gringeltaube is the guy who's opinion I'd really want on the subject. Maybe PM a pic, and ask him.

Good, absolutely! I've seen that same (2-3 fork) with much more wear and still working perfectly.... bad or good?

Yes the used lids include forksIs that lid complete with the forks?

PM sent to you.Yes the used lids include forks

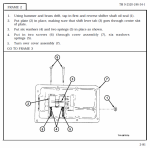

Maybe not "normal", but it still works the same and it still doesn't explain your issue..... what I did find is 3 washers on one side of the spring, and one on the other, on one shift plate bolt/shaft. On the other side, there are 2 washer on one side of the spring, and none (cover side) on the other. Is this normal?

With the top cover off, you're so close to "looking down further" already... if you haven't tried sliding 1/R and the syncros back and forth now is the time to do it. If you need to "look down further", IIRC, it's just a matter of taking the jackshaft loose, and removing the flange nut and bearing retainer, and you should be able to lift the whole mainshaft out if you want to check the counter and reverse shafts. Whether you look down further now or not, I'd certainly check the drain plug for chunkies (no need to drain the trans if the lube is good. If you don't have a spare drain plug to quickly swap in while you check for chunks on the original one, what I do is jam/thread a 1-1/4 to 1-1/2" foam ball into the drain hole while I'm looking at the plug to keep the lube from draining. After I clean the plug, I quickly swap it back in for the foam ball. I usually only lose about 1/4 cup of lube in the process) I'd also check that all your springs are present on your park brake, and that the zerks and cable are lubed and it's releasing the way it should.Yes. I seen that illustration in the TM's here. I thought at first that unequal spring pressure by washer shimming, would bind the shift plate. But the spring pressure isn't very much, the shift plate has almost no wear, and there is a lot of shifter leverage to overcome any "binding" there. So Im going to look down further AFTER I try a rebuilt top cover, but Im thinking I may be going deeper later.