rustystud

Well-known member

- 9,280

- 2,985

- 113

- Location

- Woodinville, Washington

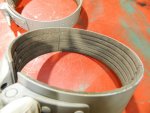

Funny that you posted this today.So, looking at making a kit for the reduction unit. With that in mind, this is a list of gaskets that would be needed....

1. Accumulator cover gasket

2. Reduction unit case halves

3. Lower valve body gasket(reduction)

4. Upper Valve body gasket(reduction)

5. Transmission to front reduction unit case half

6. "BB" pump gasket housing gasket

Did I miss anything? I don't want to tear down one of my cores to recover "BB". I will dig through some parts plowboy gasket me and see with luck if there is the mystical "BB"

This morning, I just recovered four gaskets in almost perfect condition from my other reduction unit and made a template of the large gasket using craft paper and some roll-on ink.

That "BB" gasket is for the rear pump unit.

There are three gaskets on the reduction units control valve assembly alone. Then there is the rear pump gasket ( The "BB" gasket) then the large main body gasket. So, including the "special" rear main housing gasket that makes six gaskets needed in the reduction unit. I have several rear oil seals from "Timken" coming in soon too. The Timken seal is #416273 .

This upcoming week I'll take these gaskets down into Seattle where there is a gasket specialty company that says they will make "one off" gaskets.

So that just leaves the metal seal rings and piston lip seals. I can reuse some of my lip seals and I have some pretty good seal rings. It would just be nice to find someone who actually has these items new.

Then a proper kit could be made up.

There used to be a really good transmission parts supplier in downtown Seattle by Boeing that had all makes and models of transmission parts. I could have taken the metal seal rings down there and found some that would match. Maybe a center seal ring from a Ford C-6 would fit one of the reduction units. Who knows !?!? You just need a large selection of rings to go through to find a match.

I only have a few parts left from my rebuilding days. Sadly I threw out boxes of TH400 parts last year. I had no room to store them anymore. I even throughout four Chevrolet TH400 cases too. My friend got miffed that I didn't tell him about that. My take on that was if he had come around more often, he would have seen what I was doing. Plus I didn't know he wanted TH400 parts. I did give him several 5 gallon buckets full of parts though.

Last edited: