@Browning1

If you aren't getting any fault lights when the contactor opens on its own under a light load, then I'd suspect an issue in the latching circuit that is supposed to keep the contactor closed.

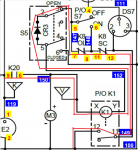

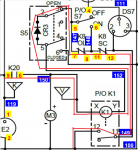

The diagram below shows the electrical path of the latching circuit. K20-9 gets 24 volts when the set is running. The path is how 24 volts gets to K1-X. K1-Y is grounded by the balance of the red path holding K1 closed.

The Yellow boxes with red text are the component terminal numbers. The blue boxes with white text are the base wire numbers. 100 is chassis ground.

If it were me, I'd do the following to find out what's causing K1 to open when it shouldn't. I'd jumper out sections of the latching path and run your set under your load and see if the problem goes away.

*** Doing some of the following steps will cause the contactor to immediately close when the set is started. ***

For example I'd put a jumper from K1-Y to chassis ground. If the problem goes away the issue is somewhere after K1-Y on its way to ground.

Assuming the problem goes away I'd remove the jumper from K1-Y and connect it to S5-5. If the problem goes away the issue is somewhere after S5-5 on its way to ground.

Repeating the process..

Assuming the problem goes away I'd remove the jumper from S5-5 and connect it to S5-2.

Run test

Assuming the problem goes away I'd remove the jumper from S5-2 and connect it to S5-3.

Run test

Assuming the problem goes away I'd remove the jumper from S5-3 and connect it to K8-7.

Run Test

Assuming the problem goes away I'd remove the jumper from K8-7 and connect it to K8-8.

Run Test

Assuming the problem goes away I'd remove the jumper from K8-8 and connect it to K8-11.

Run Test

Assuming the problem goes away I'd remove the jumper from K8-11 and connect it to K8-12.

Run Test

Assuming the problem goes away I'd remove the jumper from K8-12 and connect it to K1-11.

Run Test

Assuming the problem goes away I'd remove the jumper from K1-11 and connect it to K1-12.

At some point in the test steps above the problem will come back. When it does it'll indicate where the ground path in the latching circuit is faulty.