cbvet

Active member

- 1,567

- 20

- 38

- Location

- Northwest (Knox) Indiana

Trying to get the engine running in my M51 Shelter trailer.

Cranks fine, but no spark.

Questions:

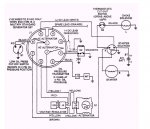

1. There is a single white wire going to the magneto. Is that wire supposed to be hot when the engine switch is on, as in a distributor system? Or does that wire go to ground when the engine switch is off, killing the engine?

2. Wiring diagram shows wires A thru J coming from AC alternator. The "alternator" behind the rope-start pulley only has 2 wires coming from it. Is diagram referring to the 3-phase generator driven by the engine?

I realize there could be a points/condenser problem, but I'm looking for simpler fixes.

I just want to see if it will run, then I'll start checking out the other components.

Appreciate any help.

Cranks fine, but no spark.

Questions:

1. There is a single white wire going to the magneto. Is that wire supposed to be hot when the engine switch is on, as in a distributor system? Or does that wire go to ground when the engine switch is off, killing the engine?

2. Wiring diagram shows wires A thru J coming from AC alternator. The "alternator" behind the rope-start pulley only has 2 wires coming from it. Is diagram referring to the 3-phase generator driven by the engine?

I realize there could be a points/condenser problem, but I'm looking for simpler fixes.

I just want to see if it will run, then I'll start checking out the other components.

Appreciate any help.