Erik Unyielding

Member

- 41

- 64

- 18

- Location

- South Shore, Massachusetts

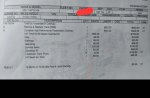

So, I got M1008 back from Pro Built Transmissions in Weymouth, MA. Those guys did a great job finding/fixing the reverse issue and did the whole 700R4 rebuild/upgrade/swap for a great price. They did a complete high performance overhaul including a Beast sun shell, HD clutch plates, Corvette servo, etc. If anyone here is in the Boston/South Shore area, I highly recommend them for all of your HP transmission needs.

I wired up the external lockup switch but I'm not 100% sure that the transmission has been modified with the correct pressure switch inside (my 700 does not have the external 4th gear pressure test port and I don't trust other people's work since it was done by the previous owner), but I believe I have the correct switch on the bench if I need it. My plan is to install a dash-mounted tach and flip the switch while cruising and check to see if the RPMs drop.

In addition to the internal upgrades and the lockup switch, I also bought a Derale 15845 Dual Cool remote cooler, that I plan on putting between the radiator and the input port of the trans, a Derale 14204 cooling pan, and a temp probe on the output line of the trans to get a good reading on the trans temp at all times.

I proudly posted about the swap on a Facebook CUCV group and it was immediately shit on by guys saying the 700R4 is trash, it's going to blow up, etc. Now, I've been in the hotrod scene for a fairly decent amount of time and the 700R4 is widely respected and regarded as one of the best automatic transmissions GM has ever produced. What gives? Does putting this trans in a 4x4 truck as opposed to a Led Sled or muscle car suddenly make the 700 a fragile hand grenade? My gut and experience told me that the upgrades and improved cooling should make the 700 as reliable in my truck as the original TH400 but since I have precious little experience with 4x4/offroad modifications, these guys have me second guessing myself.

I've come to trust the opinions on this forum above all others so I'll ask you folks: What are the limitations of this swap? Did I spend more money than the Gear Vendors OD unit only to create a weaker setup? Did I let clowns get in my head and I'm worried about nothing?

P.S. For those wondering, it's like driving a whole new truck after the swap. It cruises very comfortably at 65-70 mph and doesn't sound like it's going to throw a rod at any moment.

I wired up the external lockup switch but I'm not 100% sure that the transmission has been modified with the correct pressure switch inside (my 700 does not have the external 4th gear pressure test port and I don't trust other people's work since it was done by the previous owner), but I believe I have the correct switch on the bench if I need it. My plan is to install a dash-mounted tach and flip the switch while cruising and check to see if the RPMs drop.

In addition to the internal upgrades and the lockup switch, I also bought a Derale 15845 Dual Cool remote cooler, that I plan on putting between the radiator and the input port of the trans, a Derale 14204 cooling pan, and a temp probe on the output line of the trans to get a good reading on the trans temp at all times.

I proudly posted about the swap on a Facebook CUCV group and it was immediately shit on by guys saying the 700R4 is trash, it's going to blow up, etc. Now, I've been in the hotrod scene for a fairly decent amount of time and the 700R4 is widely respected and regarded as one of the best automatic transmissions GM has ever produced. What gives? Does putting this trans in a 4x4 truck as opposed to a Led Sled or muscle car suddenly make the 700 a fragile hand grenade? My gut and experience told me that the upgrades and improved cooling should make the 700 as reliable in my truck as the original TH400 but since I have precious little experience with 4x4/offroad modifications, these guys have me second guessing myself.

I've come to trust the opinions on this forum above all others so I'll ask you folks: What are the limitations of this swap? Did I spend more money than the Gear Vendors OD unit only to create a weaker setup? Did I let clowns get in my head and I'm worried about nothing?

P.S. For those wondering, it's like driving a whole new truck after the swap. It cruises very comfortably at 65-70 mph and doesn't sound like it's going to throw a rod at any moment.

Last edited: