Barrman

Well-known member

- 5,260

- 1,771

- 113

- Location

- Giddings, Texas

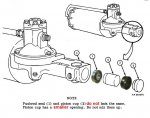

The air pack has a hydraulic side and an air side along with another part that deals with turning the air on and off. I have one apart at home and want to replace every part the kit came with. I am having trouble with the seal on the air side for the piston rod. Below are two pictures showing the new seal sitting next to the housing it is supposed to fit into.

The only way I can see to get the old seal out is bend the metal end of the housing back. I have a few extra housings sitting around and tried to gently bend the metal back on them. 3 out of 3 broke.

The more I look at the pack, the more I wonder if this seal will actually even make a difference. The piston rod goes through another bigger seal crossing over from air to hydraulic which seems to be the one that will keep the two parts seperate since its cups face the hydraulic section. The seal pictured seems to be more for keeping the air on the air side since the cups face the air piston.

Any suggestions or outright claims to just leave it as is and move on?

Thanks, Tim.

The only way I can see to get the old seal out is bend the metal end of the housing back. I have a few extra housings sitting around and tried to gently bend the metal back on them. 3 out of 3 broke.

The more I look at the pack, the more I wonder if this seal will actually even make a difference. The piston rod goes through another bigger seal crossing over from air to hydraulic which seems to be the one that will keep the two parts seperate since its cups face the hydraulic section. The seal pictured seems to be more for keeping the air on the air side since the cups face the air piston.

Any suggestions or outright claims to just leave it as is and move on?

Thanks, Tim.

Attachments

-

59.6 KB Views: 140

-

68.4 KB Views: 161