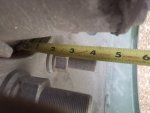

That is the hub of my M322 trailer. Take everything that you are trying to do to a 5 ton and basically imagine that that trailer hub is your 5 ton hub. Make sense? I hardly have the motivation at 95 degrees to take a 5 ton hub off, knock out 10 studs, press 10 back in, reassemble and then do all this when I don't have all the wheels and tires available. Ok so using the trailer since it has the same stud pattern. Just that the trailer is hub piloted. Just like the Hutchinson beadlocks. as you can see in the picture from the flanged cap nut marks on the wheel it is a hub piloted wheel. meaning it is not beveled for the normal 5 ton lug nuts we use. Face to face flush mount. Nothing between them. Especially no thimbles. And studs still have plenty of thread left on them.

Basically you are turning the rear of the 5 ton into a HUB piloted setup. You are going to use the same type of wheel studs that the trailer is using to allow the wheel to fit snug. It is a metric one that the trailer uses M22x1.5. You can however find it so that the serration is the same as what comes on the 5 ton. 1/2" long serration is pretty common on everything. Just have to have the right Knurl size. Knurl size on a 5 ton is .998"-.1006".

If you feel ambitious enough to do it all simply place the wheel on the studs and get it correctly measured and evened out and weld flat pieces to the hub face so that it basically has the right spot for it to sit making it a true hub pilot.

My Euclid catalog is like 400 pages on wheel studs and size charts and honestly I am not in the mood to go crosseyed at the moment to throw out all the part numbers.