- 529

- 835

- 93

- Location

- Texas Hill Country

Looking at the way we hope to use our M1078A1, an middle aged couple traveling with a dog or two in a land yacht, we hope to have a robust cab and chassis electrical and HVAC system separate from a habitat system. For many years we have camped and backpacked at more remote corners of the western US and hope to do much more with a habitat on our vehicle.

To the cab and chassis system we plan (need?) to add AC, GMRS, GPS, usb charging, stereo, power door locks, windows, and mirrors, backup and side cameras, map lighting, ecetera.

Concerns are the existing Niehoff 12/24v 100a alternator and LBCD as both appear expensive and may be difficult to replace while on the road. Our unit was purchased from a broker with 4 new batteries, though they are not AGM and only have 450cca. These batteries will likely get us through the habitat build out though will be replaced prior to any long trips, maybe sooner. The auto disconnect is also of some concern, though a new unit was installed right after purchasing our vehicle.

We welcome everyone's thoughts and suggestions.

Alternator: replace with 24v 200a (Prestolite A0014740JBH or similar, this unit has a J180 attachment that likely will require modifying the bracket, though it is a similar diameter and length to the Niehoff 12/24v 100a unit)

– requires adding 24/12v DC to DC converter (Victron Orion 2412v 70a already installed between PDP X1 and X2);

Batteries: two 12v 1150cca 100ah in series (Napa BAT9837 or similar).

@Ronmar has shown the existing electrical system operates well on two batteries even without replacing the undersized alternator. With the addition of a 24v 200a alternator a second 24v battery bank could be added to run additional accessories, including all electric AC and provide back up batteries if needed for cold starting. Replacing the LBCD with a smart battery combiner accomplishes this goal well and eliminates a potentially expensive and difficult part to locate.

LBCD: replace with a smart battery combiner (Victrom Cyrix-ct 220a or similar);

– rewire the feed to IAH relay and add a voltage sensor connected to the dash indicator light;

– add a second two 12v 1150cca 100ah in series (Napa BAT9837 or similar) to run non-essential accessories.

Add a Victron Smart Battery Protect 220a between the non-essential loads and second battery bank to insure the batteries are not depleted while engine is off.

Such accessories could include an electrical roof top 24v AC (Nomadic X3 24v AC or RedDot E-6100) drawing 55a to produce 12,480btu, along with power door locks, windows and mirrors, back up and side view cameras and screens. Stereo, Sirius and GMRS radios. GPS and usb chargers for tablets, phones, laptop, handheld gps. Anticipated 24v load would be between 100a - 150a.

An electrical AC unit offers plusses and minuses. On the plus side with a larger alternator it eliminates yet another added load from a compressor (minor plus), allows AC use while the engine is off, and potentially being wired into the much large habitat system in the future. On the minus side it is less than 15,000btu and the Gen2 RedDot dash units provide over 30,000btu? Our 2,600 sqft house has only 48,000btu of cooling so, 30,000 sounds like more than we need, but I could be wrong as the house is much better insulated than the cab will be even after we insulate it.

It sounds complicated, though it uses much of the existing wiring while replacing items that are either difficult to locate while traveling, more expensive than needed, or underrated for the potenial loads in a straight forward, easy to maintain way.

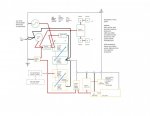

NOT USED Here is the simple schematic in progress REVISED BELOW in post 19:

Thank you for your comments and suggestions. We are looking forward to making it better–

To the cab and chassis system we plan (need?) to add AC, GMRS, GPS, usb charging, stereo, power door locks, windows, and mirrors, backup and side cameras, map lighting, ecetera.

Concerns are the existing Niehoff 12/24v 100a alternator and LBCD as both appear expensive and may be difficult to replace while on the road. Our unit was purchased from a broker with 4 new batteries, though they are not AGM and only have 450cca. These batteries will likely get us through the habitat build out though will be replaced prior to any long trips, maybe sooner. The auto disconnect is also of some concern, though a new unit was installed right after purchasing our vehicle.

We welcome everyone's thoughts and suggestions.

Alternator: replace with 24v 200a (Prestolite A0014740JBH or similar, this unit has a J180 attachment that likely will require modifying the bracket, though it is a similar diameter and length to the Niehoff 12/24v 100a unit)

– requires adding 24/12v DC to DC converter (Victron Orion 2412v 70a already installed between PDP X1 and X2);

Batteries: two 12v 1150cca 100ah in series (Napa BAT9837 or similar).

@Ronmar has shown the existing electrical system operates well on two batteries even without replacing the undersized alternator. With the addition of a 24v 200a alternator a second 24v battery bank could be added to run additional accessories, including all electric AC and provide back up batteries if needed for cold starting. Replacing the LBCD with a smart battery combiner accomplishes this goal well and eliminates a potentially expensive and difficult part to locate.

LBCD: replace with a smart battery combiner (Victrom Cyrix-ct 220a or similar);

– rewire the feed to IAH relay and add a voltage sensor connected to the dash indicator light;

– add a second two 12v 1150cca 100ah in series (Napa BAT9837 or similar) to run non-essential accessories.

Add a Victron Smart Battery Protect 220a between the non-essential loads and second battery bank to insure the batteries are not depleted while engine is off.

Such accessories could include an electrical roof top 24v AC (Nomadic X3 24v AC or RedDot E-6100) drawing 55a to produce 12,480btu, along with power door locks, windows and mirrors, back up and side view cameras and screens. Stereo, Sirius and GMRS radios. GPS and usb chargers for tablets, phones, laptop, handheld gps. Anticipated 24v load would be between 100a - 150a.

An electrical AC unit offers plusses and minuses. On the plus side with a larger alternator it eliminates yet another added load from a compressor (minor plus), allows AC use while the engine is off, and potentially being wired into the much large habitat system in the future. On the minus side it is less than 15,000btu and the Gen2 RedDot dash units provide over 30,000btu? Our 2,600 sqft house has only 48,000btu of cooling so, 30,000 sounds like more than we need, but I could be wrong as the house is much better insulated than the cab will be even after we insulate it.

It sounds complicated, though it uses much of the existing wiring while replacing items that are either difficult to locate while traveling, more expensive than needed, or underrated for the potenial loads in a straight forward, easy to maintain way.

NOT USED Here is the simple schematic in progress REVISED BELOW in post 19:

Thank you for your comments and suggestions. We are looking forward to making it better–

Last edited: