General Mcgregor

Member

- 980

- 24

- 18

- Location

- Dover, New Hampshire

Hey fellas!

Well it's been nearly 3 years since I bought my M66 ring mount but I still don't have a replica weapon to complete the setup. I have been looking at replicas on epay and other places that do 1:1 builds of famous weapons but holy $$$$!!

I can't justify paying $1500 plus for a .50 cal Ma Deuce replica. And I'm not about to buy one that I can break over my knee either.

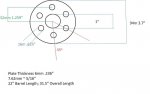

So I have been left with no other option, I am going to build myself a replica machine gun from scratch. And I figured I might as well go all out! I am going to build a tribute to Ol' Painless, the M134 Minigun! (more like the GAU 17A door gun).

This replica will be slightly larger than the compact M134 (It will be more like .50 caliber barrels) but much smaller than the Vulcan 20mm.

There are a few requirements that I have for the finished product.

1. Must be as close to the design of the weapon as possible with the resources I have at my disposal.

2. The replica must have a working rotational mechanism with an electric motor that can spin the barrels up to 2500 rpm (or close).

3. The replica must also have a mount that attaches to the M66 ring (or any military tripod).

4. Must be constructed of as many metal parts as possible to maintain realism.

5. Must be finished before spring.

I really hope to finish this build and am looking forward to posting pictures and updates about my progress. I figure it will make a nice project to keep me busy this winter. If anyone has done anything similar or has any input at all about good parts or construction materials to use I would very much encourage you to subscribe to this thread!

Design work starts tonight with some prep work starting hopefully this week.

Here are a couple pics of what I hope to have for a finished product.

Well it's been nearly 3 years since I bought my M66 ring mount but I still don't have a replica weapon to complete the setup. I have been looking at replicas on epay and other places that do 1:1 builds of famous weapons but holy $$$$!!

I can't justify paying $1500 plus for a .50 cal Ma Deuce replica. And I'm not about to buy one that I can break over my knee either.

So I have been left with no other option, I am going to build myself a replica machine gun from scratch. And I figured I might as well go all out! I am going to build a tribute to Ol' Painless, the M134 Minigun! (more like the GAU 17A door gun).

This replica will be slightly larger than the compact M134 (It will be more like .50 caliber barrels) but much smaller than the Vulcan 20mm.

There are a few requirements that I have for the finished product.

1. Must be as close to the design of the weapon as possible with the resources I have at my disposal.

2. The replica must have a working rotational mechanism with an electric motor that can spin the barrels up to 2500 rpm (or close).

3. The replica must also have a mount that attaches to the M66 ring (or any military tripod).

4. Must be constructed of as many metal parts as possible to maintain realism.

5. Must be finished before spring.

I really hope to finish this build and am looking forward to posting pictures and updates about my progress. I figure it will make a nice project to keep me busy this winter. If anyone has done anything similar or has any input at all about good parts or construction materials to use I would very much encourage you to subscribe to this thread!

Design work starts tonight with some prep work starting hopefully this week.

Here are a couple pics of what I hope to have for a finished product.

Attachments

-

23.2 KB Views: 99

-

10.7 KB Views: 95

-

23.8 KB Views: 112

-

101 KB Views: 133

Last edited by a moderator: