sangamon

New member

- 49

- 0

- 0

- Location

- Seattle / Blaine

[FONT=Liberation Sans, sans-serif]I've started my project to loosen up the steering on my M656. This will reduce the torque required to move the tie rod ends from 100+ foot pounds to about 10 foot pounds. Since there are eleven of these ends, they add up to a lot of torque resistance. The two main external symptoms are very stiff steering, and wandering as the joints suddenly move as the force builds. I haven't put a torque wrench on anything yet. However, trying to move a six or seven foot long tie rod with one end still attached was very difficult.[/FONT]

[FONT=Liberation Sans, sans-serif]There are eleven tie rod ends that need to be removed. Then, the ends are heated for four hours in 280 degree oil. This technique was developed by cranetruck.[/FONT]

[FONT=Liberation Sans, sans-serif]I have attached a variety of pictures that I took during the first part of the project.[/FONT]

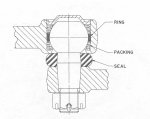

[FONT=Liberation Sans, sans-serif]The first picture is the steering diagram from the tech manual with the rod ends circled (thanks to cranetruck), with my numbers. I use this diagram to tag each end for reassembly.[/FONT]

[FONT=Liberation Sans, sans-serif]I was able to “easily” loosen numbers 3, 4, 5, 6, 7, and 10. I used a pickle fork (KD Tools 3316), along with side-tapping, and end tapping. The easiest only took three taps with my hammer.[/FONT]

[FONT=Liberation Sans, sans-serif]I have not yet tried number 1, which connects the steering cylinder rod to the frame.[/FONT]

[FONT=Liberation Sans, sans-serif]For number 2, which connects the pitman arm to the front drag link, I can't get the castle nut to move, even with a long pipe. This is odd, because the other nuts were easy. I'll try with an impact wrench next trip.[/FONT]

[FONT=Liberation Sans, sans-serif]Number 9, which connects the rear reach rod to the second steering axle driver side wheel, absolutely will not move. I've used a wide variety of banging and prying to no avail. I suspect that there's pressure on it from number 5 at the front of the reach rod, where it connects to the idler arm. Next trip, I'm going to put number 5 back in place, which will hopefully reduce any side loading, and try again.[/FONT]

[FONT=Liberation Sans, sans-serif]I haven't seriously tried removing number 8 and number 10, because the right side tires are still on the truck.[/FONT]

[FONT=Liberation Sans, sans-serif]I brought home numbers 3, 6, 7, and 10. Even though 4 and 5 are loose, the other ends of the rods are keeping them on the truck. And, while writing this I note that the (removed) rod with two ends in one picture is incorrectly tagged as 3 and 4, when it should be 3 and 6.[/FONT]

[FONT=Liberation Sans, sans-serif]I'll pick up a cheap electric deep fryer and thermometer this weekend and start cooking.[/FONT]

[FONT=Liberation Sans, sans-serif]Oh, and the M656 doesn't have left hand threads on lug nuts on the left side. It's righty-tighty on both sides.[/FONT]

[FONT=Liberation Sans, sans-serif]More later.[/FONT]

[FONT=Liberation Sans, sans-serif]There are eleven tie rod ends that need to be removed. Then, the ends are heated for four hours in 280 degree oil. This technique was developed by cranetruck.[/FONT]

[FONT=Liberation Sans, sans-serif]I have attached a variety of pictures that I took during the first part of the project.[/FONT]

[FONT=Liberation Sans, sans-serif]The first picture is the steering diagram from the tech manual with the rod ends circled (thanks to cranetruck), with my numbers. I use this diagram to tag each end for reassembly.[/FONT]

[FONT=Liberation Sans, sans-serif]I was able to “easily” loosen numbers 3, 4, 5, 6, 7, and 10. I used a pickle fork (KD Tools 3316), along with side-tapping, and end tapping. The easiest only took three taps with my hammer.[/FONT]

[FONT=Liberation Sans, sans-serif]I have not yet tried number 1, which connects the steering cylinder rod to the frame.[/FONT]

[FONT=Liberation Sans, sans-serif]For number 2, which connects the pitman arm to the front drag link, I can't get the castle nut to move, even with a long pipe. This is odd, because the other nuts were easy. I'll try with an impact wrench next trip.[/FONT]

[FONT=Liberation Sans, sans-serif]Number 9, which connects the rear reach rod to the second steering axle driver side wheel, absolutely will not move. I've used a wide variety of banging and prying to no avail. I suspect that there's pressure on it from number 5 at the front of the reach rod, where it connects to the idler arm. Next trip, I'm going to put number 5 back in place, which will hopefully reduce any side loading, and try again.[/FONT]

[FONT=Liberation Sans, sans-serif]I haven't seriously tried removing number 8 and number 10, because the right side tires are still on the truck.[/FONT]

[FONT=Liberation Sans, sans-serif]I brought home numbers 3, 6, 7, and 10. Even though 4 and 5 are loose, the other ends of the rods are keeping them on the truck. And, while writing this I note that the (removed) rod with two ends in one picture is incorrectly tagged as 3 and 4, when it should be 3 and 6.[/FONT]

[FONT=Liberation Sans, sans-serif]I'll pick up a cheap electric deep fryer and thermometer this weekend and start cooking.[/FONT]

[FONT=Liberation Sans, sans-serif]Oh, and the M656 doesn't have left hand threads on lug nuts on the left side. It's righty-tighty on both sides.[/FONT]

[FONT=Liberation Sans, sans-serif]More later.[/FONT]

Attachments

-

89.2 KB Views: 79

-

100.8 KB Views: 80

-

100.8 KB Views: 75

-

101.6 KB Views: 78

-

91 KB Views: 73

-

90.2 KB Views: 73

-

75.8 KB Views: 72

-

59.1 KB Views: 72

-

70 KB Views: 71

-

62.5 KB Views: 76

-

85.4 KB Views: 73

-

53.6 KB Views: 92

-

100.1 KB Views: 86

-

94.1 KB Views: 79

-

94.6 KB Views: 80

-

99.4 KB Views: 73

-

91.8 KB Views: 76

-

97.5 KB Views: 74

-

64.1 KB Views: 73