- 1,629

- 724

- 113

- Location

- Central NY

Picked up a pair of real heavy snatch blocks. Thought I'd tear them down and lube everything. Surprised to see sheave was running on a double ring of roller bearings.

5 finger bolt head, obviously doesn't fit any (ordinary) spanner/socket, so I went straight to slogging at it with a big aluminium drift.

Tan one yielded quickly, (zero wear on sheave .. paint intact!). However the green one would not give up at all, even with some heat on the captive nut [read good heat sync to cheek plate - must try hotter]. I may have to grind the weld on the nut to release it, then reweld.

Sheave is good for 1.050" dia, which is a smidge under 1 & 1/16", but since cables are measured point to point, not flat (pair of strands) to flat, I am sure 1 & 1/8" cable would work, never the less, prob designed for 1" as sheave dia isn't even as big as the 7/8" one I have for M916A1 winch.

I believe these were Bii for the M747 (60 ton 4 axle) trailer, pulled by the M911 HET.

There was a huge pin that came with the green one. Not sure how the snatch block would be rigged, I would have thought that a large shackle would have been used to connect to the casualty vehicle.

8 finger/tab nuts are retained by an allen head screw and clamp the cheek plates to the sheeve spindle.

8 tab nut removed from green one.

Bottom center, the 5 point bolt head, which is supposed to be hand tight++ which breaks the block apart to insert the cable.

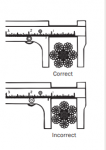

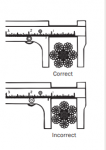

Measuring cable size of the sheeve. I usually use coins when I come across them at a show: 25c - 15/16", 5c - 13/16", 1c -3/4", 10c - 11/16". So although juggeling 1/16"s is a stretch for my metric brain, compensating for the "correct" way to measure steel cable, allows me to 'round down' to the nearest 1/8" which seems to be the increments that cable is made in.

8 finger nuts from the sheeve spindles and short allen headed screw.

I don't actually need these, so if anyone is interested, LMK. Can bring to Findlay, Weare NH or Redball PA in fall.

5 finger bolt head, obviously doesn't fit any (ordinary) spanner/socket, so I went straight to slogging at it with a big aluminium drift.

Tan one yielded quickly, (zero wear on sheave .. paint intact!). However the green one would not give up at all, even with some heat on the captive nut [read good heat sync to cheek plate - must try hotter]. I may have to grind the weld on the nut to release it, then reweld.

Sheave is good for 1.050" dia, which is a smidge under 1 & 1/16", but since cables are measured point to point, not flat (pair of strands) to flat, I am sure 1 & 1/8" cable would work, never the less, prob designed for 1" as sheave dia isn't even as big as the 7/8" one I have for M916A1 winch.

I believe these were Bii for the M747 (60 ton 4 axle) trailer, pulled by the M911 HET.

There was a huge pin that came with the green one. Not sure how the snatch block would be rigged, I would have thought that a large shackle would have been used to connect to the casualty vehicle.

8 finger/tab nuts are retained by an allen head screw and clamp the cheek plates to the sheeve spindle.

8 tab nut removed from green one.

Bottom center, the 5 point bolt head, which is supposed to be hand tight++ which breaks the block apart to insert the cable.

Measuring cable size of the sheeve. I usually use coins when I come across them at a show: 25c - 15/16", 5c - 13/16", 1c -3/4", 10c - 11/16". So although juggeling 1/16"s is a stretch for my metric brain, compensating for the "correct" way to measure steel cable, allows me to 'round down' to the nearest 1/8" which seems to be the increments that cable is made in.

8 finger nuts from the sheeve spindles and short allen headed screw.

I don't actually need these, so if anyone is interested, LMK. Can bring to Findlay, Weare NH or Redball PA in fall.

Last edited: