mistaken1

New member

- 1,467

- 6

- 0

- Location

- Kansas City, KS

Well I went to exercise the MEP-002A on Sunday before the big storm and needless to stay it suddenly died.

It wants to start right up but as soon as I let go of the starter switch it dies. If I hold the starter switch in the start position it runs.

It had only been running 15 minutes or so and it was cold outside (still is) so I do not think that the temperature switch is the culprit.

The oil pressure gauge showed 30# when running and would quickly return to 30# when the start switch is held. So I jumpered out the low oil pressure switch and wouldn't you know it the unit runs with the same 30# of pressure on the gauge. (the gauge started out at 0# and went to just over 35# when first started and then as the unit warmed settled down to its normal 30#).

So either my gauge is bad and pressure switch is saving my engine or my gauge is accurate and my pressure switch is broken (or clogged).

On to my questions to those with more experience:

Which is more likely to be broken the gauge or the pressure switch?

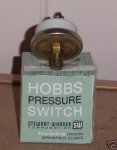

I am assuming the pressure switch and am looking for another and this is what I find.

I have not had any luck finding any of these exact numbers but I did find some things that are close to the Hobbs M-4008-14 and by close I mean I see no reason why they will not work but again want the feedback of those more experienced.

The Hobbs 76052-15 is a SPST NO screw terminal pressure switch (1/8-27 NPT) that is adjustable between 14 and 24 psi and is factory set at 15 psi.

Will this Hobbs 76052-15 work as a replacement for the original Hobbs M-4008-14?

76052-15 - Hobbs (replaces 4008-15) | Translectric, Inc. The Heavy Duty Parts Pros

HONEYWELL HOBBS 76052-15 is in stock|Buy7605215|76052 15|Onlinecomponents.com

Thanks in advance.

It wants to start right up but as soon as I let go of the starter switch it dies. If I hold the starter switch in the start position it runs.

It had only been running 15 minutes or so and it was cold outside (still is) so I do not think that the temperature switch is the culprit.

The oil pressure gauge showed 30# when running and would quickly return to 30# when the start switch is held. So I jumpered out the low oil pressure switch and wouldn't you know it the unit runs with the same 30# of pressure on the gauge. (the gauge started out at 0# and went to just over 35# when first started and then as the unit warmed settled down to its normal 30#).

So either my gauge is bad and pressure switch is saving my engine or my gauge is accurate and my pressure switch is broken (or clogged).

On to my questions to those with more experience:

Which is more likely to be broken the gauge or the pressure switch?

I am assuming the pressure switch and am looking for another and this is what I find.

5930-01-039-3140 Master Cross Reference Data

Mfg. Part Number

3090177

76052-14

C0309017700

M-1423-14-S2

M-4008-14

M1423-14

SM-2A-14F

76052-14

C0309017700

M-1423-14-S2

M-4008-14

M1423-14

SM-2A-14F

The Hobbs 76052-15 is a SPST NO screw terminal pressure switch (1/8-27 NPT) that is adjustable between 14 and 24 psi and is factory set at 15 psi.

Will this Hobbs 76052-15 work as a replacement for the original Hobbs M-4008-14?

76052-15 - Hobbs (replaces 4008-15) | Translectric, Inc. The Heavy Duty Parts Pros

HONEYWELL HOBBS 76052-15 is in stock|Buy7605215|76052 15|Onlinecomponents.com

Thanks in advance.