- 16,707

- 23,948

- 113

- Location

- Burgkunstadt, Germany

THIS INFO IS FROM THE P.S. Magazine.

NEWS | Nov. 28, 2022

MEP-1050 Generator: Oil Slobbering Solution

BLUF: The MEP-1050 generator’s oil breather joint assembly can clog, resulting in misdiagnosis.

Photo courtesy of ASC

Dear Editor,

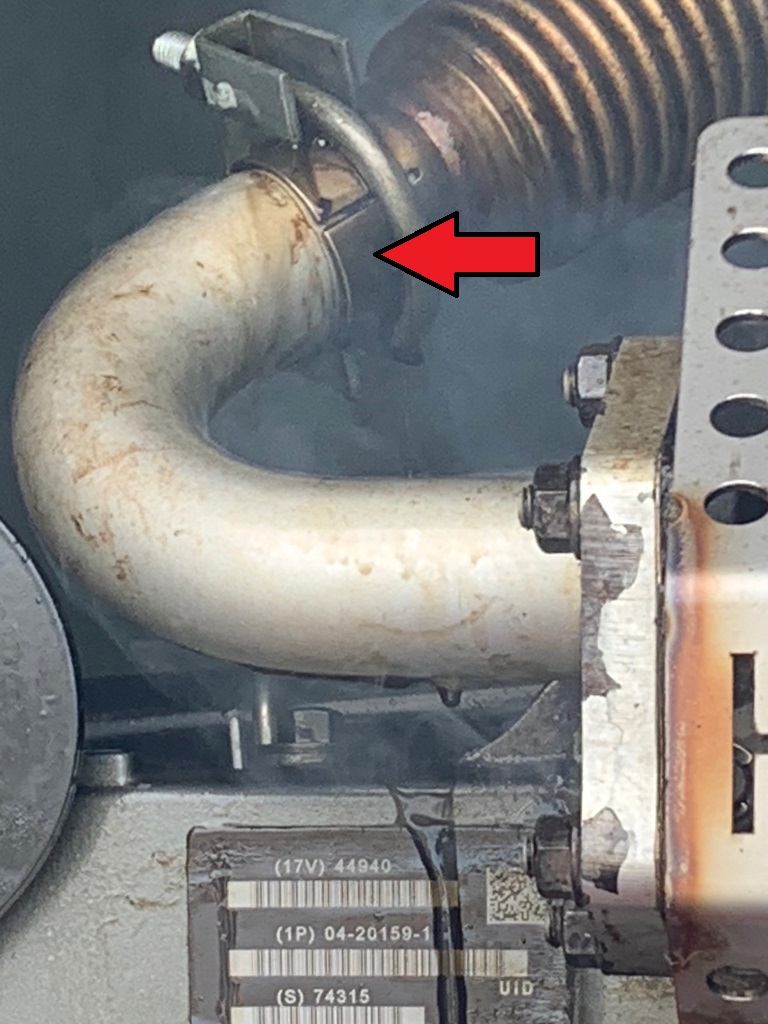

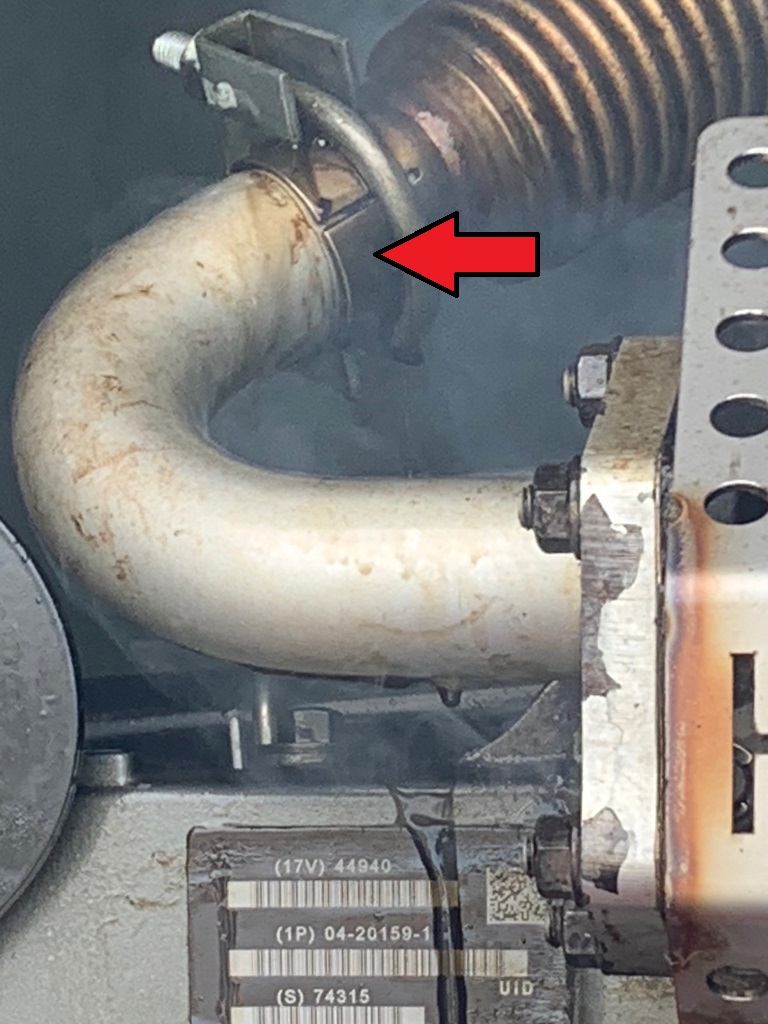

Soldiers in the field have seen issues with oil slobbering out of the exhaust side of the turbocharger on the MEP-1050 generator, commonly known as the 15-kW Advanced Medium Mobile Power Source (AMMPS) generator. This often happens with less than 100 hours of operation. The issue is frequently misdiagnosed as a bad turbocharger assembly. When the new part comes in and is installed, the problem returns.

Oil slobbering on MEP-1050

Units are needlessly spending time and money on what could be solved by a quick check of the oil breather assembly. Before spending over $1,400 to order and replace that turbo, Soldiers need to look at the oil breather joint assembly.

Per WP 19 in TM 9-6115-751-24&P (Nov 15), the joint attached between two hoses which go to the air filter assembly with a T-coupling is connected to a hose going to the valve cover assembly. Removing the flange per WP 19 could reveal that the breather hole in the T-coupling is clogged with a fiberglass-looking material.

Oil breather joint blockage by fiberglass-like material

When the breather hole is clogged, oil vapors can’t easily vent from the crankcase while the engine is running, leading to backpressure in the engine. That oil vapor needs to escape, and the two paths of least resistance are the oil dipstick tube and, most frequently, the exhaust side of the turbocharger.

The oil breather joint allows oil vapors to escape. It’s an easy item to inspect. Soldiers can quickly inspect it during the 50-hour PMCS while replacing the break-in oil. When clogged as shown below, use a rag and a scribe to clean the T-coupling and remove material from the hole.

Check for clogged oil breather joint

The turbocharger is designed to last for the entire lifetime of the engine if it receives the prescribed periodic oil and filter changes. A failing turbocharger could make an acoustic noise before it fails, but that’s not always a given. A failing turbocharger may also lead to a drop in overall engine power, and the air intake filter should be checked for a clog or resistance prior to diagnosing the turbocharger.

If troubleshooting indicates the problem is the turbocharger, before replacing the turbocharger assembly, the internal components need inspecting. That entails removing the assembly, inspecting the impeller wheels for damage, and ensuring that the rotor spins freely and without restriction per WP 78 in TM 9-6115-751-24&P.

Similar oil slobbering issues have happened on the MEP-1030 (5-kW AMMPS) and MEP-1040 (10-kW AMMPS) generators. Soldiers should consult the equipment TMs for inspection instructions.

NEWS | Nov. 28, 2022

MEP-1050 Generator: Oil Slobbering Solution

BLUF: The MEP-1050 generator’s oil breather joint assembly can clog, resulting in misdiagnosis.

Photo courtesy of ASC

Dear Editor,

Soldiers in the field have seen issues with oil slobbering out of the exhaust side of the turbocharger on the MEP-1050 generator, commonly known as the 15-kW Advanced Medium Mobile Power Source (AMMPS) generator. This often happens with less than 100 hours of operation. The issue is frequently misdiagnosed as a bad turbocharger assembly. When the new part comes in and is installed, the problem returns.

Oil slobbering on MEP-1050

Units are needlessly spending time and money on what could be solved by a quick check of the oil breather assembly. Before spending over $1,400 to order and replace that turbo, Soldiers need to look at the oil breather joint assembly.

Per WP 19 in TM 9-6115-751-24&P (Nov 15), the joint attached between two hoses which go to the air filter assembly with a T-coupling is connected to a hose going to the valve cover assembly. Removing the flange per WP 19 could reveal that the breather hole in the T-coupling is clogged with a fiberglass-looking material.

Oil breather joint blockage by fiberglass-like material

When the breather hole is clogged, oil vapors can’t easily vent from the crankcase while the engine is running, leading to backpressure in the engine. That oil vapor needs to escape, and the two paths of least resistance are the oil dipstick tube and, most frequently, the exhaust side of the turbocharger.

The oil breather joint allows oil vapors to escape. It’s an easy item to inspect. Soldiers can quickly inspect it during the 50-hour PMCS while replacing the break-in oil. When clogged as shown below, use a rag and a scribe to clean the T-coupling and remove material from the hole.

Check for clogged oil breather joint

The turbocharger is designed to last for the entire lifetime of the engine if it receives the prescribed periodic oil and filter changes. A failing turbocharger could make an acoustic noise before it fails, but that’s not always a given. A failing turbocharger may also lead to a drop in overall engine power, and the air intake filter should be checked for a clog or resistance prior to diagnosing the turbocharger.

If troubleshooting indicates the problem is the turbocharger, before replacing the turbocharger assembly, the internal components need inspecting. That entails removing the assembly, inspecting the impeller wheels for damage, and ensuring that the rotor spins freely and without restriction per WP 78 in TM 9-6115-751-24&P.

Similar oil slobbering issues have happened on the MEP-1030 (5-kW AMMPS) and MEP-1040 (10-kW AMMPS) generators. Soldiers should consult the equipment TMs for inspection instructions.