jaybird67k

Active member

- 103

- 25

- 28

- Location

- Texas

So first off thanks for all the help on my genset. My last post started as something else then wandered off when I found my M8 % load gauge isn't working.

Several on here had some great suggestions for troubleshooting and provided some good diagrams.

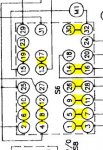

I'm currently looking for a good diagram of the S6 swith because it's difficult to read with the wires in the way.

I have tested continuity on almost all of the connections in the diagram with good results. The resistor R11 I'm assuming needs to be disconnected to actually test resistance?

I have continuity across it.

Thanks, Jason

Several on here had some great suggestions for troubleshooting and provided some good diagrams.

I'm currently looking for a good diagram of the S6 swith because it's difficult to read with the wires in the way.

I have tested continuity on almost all of the connections in the diagram with good results. The resistor R11 I'm assuming needs to be disconnected to actually test resistance?

I have continuity across it.

Thanks, Jason

Attachments

-

656.2 KB Views: 8

-

195.5 KB Views: 8