loosegravel

Just a retired mechanic who's having fun!

- 504

- 890

- 93

- Location

- Enumclaw, Washington

I posted a thread a few days ago entitled “MEP-831A fuel pump.” I had recently acquired this machine from auction in non running condition. My first problem was no fuel out of the fuel pump. That problem has since been resolved. I figured that I should start a different thread now because I’m no longer dealing with fuel pump problems.

I received some great help in that thread which led me to know that I would need to tear into this L70 Yanmar engine much deeper at a later date. Well, today was the day for tearing it down. I knew that I had some issues in the rotating mass, as I could “feel” it and I could “hear” it. As Ray previously mentioned, a spun rod bearing could reduce the compression just enough so it wouldn’t fire on its own. It was getting plenty of fuel while cranking it over because of all of the white smoke, but it wouldn’t light off (or stay running) without a snort of either. I fully expected to find what Ray said after tearing it down. But what I actually found was a bent rod. There’s been no contact between the piston and the valves that I can see. What I was feeling and hearing when turning the engine over by hand was the bottom of the piston crown coming in contact with the counter weights on the crankshaft. Usually when I see a bent rod like this on a water cooled engine it’s because of water or coolant intrusion into the combustion chamber and the piston “hydraulics” on the compression stroke. So I’m really scratching my head on how this could happen on an air cooled engine

But, none the less this engine is very good otherwise. I know we should not rely on the hour meters on these machines, but this unit has about 350 hours and it shows very little wear. I’ve ordered a replacement rod with the bearings. I’ve also ordered a rebuild kit with the gaskets, roller bearings, and some other miscellaneous parts.

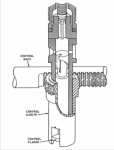

I’m also looking for some guidance on the compression release on this engine. The engine was partially torn apart when I got this generator, missing the exhaust rocker arm and push rod. I’ve got those parts now, but it appears that it’s missing something on the inside of the rocker cover that would make contact with the exhaust rocker arm when the red lever on the outside of the valve cover is pushed down. (The red lever and the shaft is there on the valve cover) In looking at the TM’s, there’s also a “valve cap” on the exhaust valve that’s not here on this engine. Thanks!

I received some great help in that thread which led me to know that I would need to tear into this L70 Yanmar engine much deeper at a later date. Well, today was the day for tearing it down. I knew that I had some issues in the rotating mass, as I could “feel” it and I could “hear” it. As Ray previously mentioned, a spun rod bearing could reduce the compression just enough so it wouldn’t fire on its own. It was getting plenty of fuel while cranking it over because of all of the white smoke, but it wouldn’t light off (or stay running) without a snort of either. I fully expected to find what Ray said after tearing it down. But what I actually found was a bent rod. There’s been no contact between the piston and the valves that I can see. What I was feeling and hearing when turning the engine over by hand was the bottom of the piston crown coming in contact with the counter weights on the crankshaft. Usually when I see a bent rod like this on a water cooled engine it’s because of water or coolant intrusion into the combustion chamber and the piston “hydraulics” on the compression stroke. So I’m really scratching my head on how this could happen on an air cooled engine

But, none the less this engine is very good otherwise. I know we should not rely on the hour meters on these machines, but this unit has about 350 hours and it shows very little wear. I’ve ordered a replacement rod with the bearings. I’ve also ordered a rebuild kit with the gaskets, roller bearings, and some other miscellaneous parts.

I’m also looking for some guidance on the compression release on this engine. The engine was partially torn apart when I got this generator, missing the exhaust rocker arm and push rod. I’ve got those parts now, but it appears that it’s missing something on the inside of the rocker cover that would make contact with the exhaust rocker arm when the red lever on the outside of the valve cover is pushed down. (The red lever and the shaft is there on the valve cover) In looking at the TM’s, there’s also a “valve cap” on the exhaust valve that’s not here on this engine. Thanks!