98hd

Member

- 552

- 1

- 18

- Location

- Reedsburg, WI / Trenary, MI

Went to start my M818 this past weekend, and got nothing. I flipped the batt switch everything was as normal. Flipped the other switch to start and it wouldn't turn over. The batt gauge went into the yellow, but nothing still.

I thought maybe batt's were really low, so I slaved over my M342 w/ 2 brand new walmart special group 65's. Still same symptoms.

In the past I've had nothing happen when flipping the switch to start, but trying it again a few times and it would start.

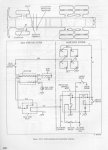

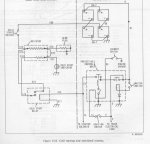

So does it sound like a control box? Any way to check the box or bypass it? I hear they are expensive.

I thought maybe batt's were really low, so I slaved over my M342 w/ 2 brand new walmart special group 65's. Still same symptoms.

In the past I've had nothing happen when flipping the switch to start, but trying it again a few times and it would start.

So does it sound like a control box? Any way to check the box or bypass it? I hear they are expensive.