No.2Diesel

New member

- 1,264

- 11

- 0

- Location

- Huntington, NY

Hi,

The following is a little show & tell/review of a nice new tool I picked up at the Sussex, NJ show this past weekend. I had seen one on the classifieds here and thought it was pretty neat so when I spied one at the show I immediately purchased it. There was another there and I kick myself for not getting it. This particular model has a Quality Control date of 1998 and the entire kit looks as if it has never been used.

This mechanical wrench kit model PD704 is/was issued to tanker maintenance crews for loosening and torquing of fasteners on track assemblies such as: track pads, track end connector, and track center guides. It comes in a nice heavy duty case with a foam insert to tightly hold all the bits and pieces. Also inside is a torque calibration certificate at different torque settings up to 600ft.lbs. Instructions are provided on thick plastic cards that are three-hole-punched held together by locking rings for use in the field.

This kit allows one to use the adapter specified for track related items but it also comes with a reaction bar for everything else. All you need to supply is a length of pipe. The method of input is 3/8" sq. drive. A crank handle and a ratcheting 3/8" wrench is provided for use in tight quarters. Torque output is by way of a 3/4" drive bar. Three Snap-On 12 point 3/4" drive sockets are also provided in the common sizes for use on heavy tracked vehicles. They are: 15/16", 1-1/8", and 1-5/16". Two hex head cap screws and an Allen key wrench are provided. The adapter is fastened to the torque head so you don't have to juggle/drop all the items to get setup or change locations.

I didn't notice until after I got home that this thing had a torque dial gauge. It hides under a polished stainless hinged cover that acts as a mirror to view the torque reading in different positions...pretty neat stuff. For kicks I was curious to see what gear ratio of this thing was due to the small crank handle and large output torque rating. I inserted the crank handle and actually sat there counting them off. It takes 132 rotations of the input drive to rotate the output drive once..."nice-oh"

Lug nuts and pinion yoke nuts immediately came to mind upon purchase. So after work I tried it out on my Deuce. I already have my trusty Ken-Tool wrench so I wanted to see how this unit compares. Due to the insane gear ratio, torquing or loosening a lug nut is like turning the handle on a pencil sharpener.

When I use the Ken-Tool wrench I only use the small drive bar (no pipe over it) when tightening and go until I hear the nuts "creak" on their seats. The gauge on the PowerDyne approached the 600 mark before the nut popped. I didn't like the shock load it put on the unit when the nut popped so if I use it again I will loosen them all the with Ken-Tool.

Overall opinion: I'm pretty fast with the Ken-Tool and it doesn't take up alot of storage space and fits in my bag in the driver side running board toolbox. The PowerDyne unit takes up more space and still needs a 3/4" drive extension if you want to use the crank handle for doing lug nuts. A huge plus for the PowerDyne however is I noticed that in both directions I did not need a jackstand for stability and I'm not juggling and resetting the position of drive bars, reaction bars, pipes etc. as with the Ken-Tool. Its much less combersome. You also don't have to work too hard either. The other huge plus for this thing is that it has a torque gauge. Most people only have a 1/2" drive click type torque wrench in their box so this is great for torquing those larger misc. fasteners without having to buy a $$$ torque wrench.

In terms of price I don't know what the Gov't acquisition cost was/is but I'd guess at least $1,500-1,700 and more. The three 12pt. sockets alone retail for $38, $39, and $50 respectively. The 12 point reaction bar box wrench retails for about $110.

Enjoy the pics!!

The following is a little show & tell/review of a nice new tool I picked up at the Sussex, NJ show this past weekend. I had seen one on the classifieds here and thought it was pretty neat so when I spied one at the show I immediately purchased it. There was another there and I kick myself for not getting it. This particular model has a Quality Control date of 1998 and the entire kit looks as if it has never been used.

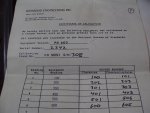

This mechanical wrench kit model PD704 is/was issued to tanker maintenance crews for loosening and torquing of fasteners on track assemblies such as: track pads, track end connector, and track center guides. It comes in a nice heavy duty case with a foam insert to tightly hold all the bits and pieces. Also inside is a torque calibration certificate at different torque settings up to 600ft.lbs. Instructions are provided on thick plastic cards that are three-hole-punched held together by locking rings for use in the field.

This kit allows one to use the adapter specified for track related items but it also comes with a reaction bar for everything else. All you need to supply is a length of pipe. The method of input is 3/8" sq. drive. A crank handle and a ratcheting 3/8" wrench is provided for use in tight quarters. Torque output is by way of a 3/4" drive bar. Three Snap-On 12 point 3/4" drive sockets are also provided in the common sizes for use on heavy tracked vehicles. They are: 15/16", 1-1/8", and 1-5/16". Two hex head cap screws and an Allen key wrench are provided. The adapter is fastened to the torque head so you don't have to juggle/drop all the items to get setup or change locations.

I didn't notice until after I got home that this thing had a torque dial gauge. It hides under a polished stainless hinged cover that acts as a mirror to view the torque reading in different positions...pretty neat stuff. For kicks I was curious to see what gear ratio of this thing was due to the small crank handle and large output torque rating. I inserted the crank handle and actually sat there counting them off. It takes 132 rotations of the input drive to rotate the output drive once..."nice-oh"

Lug nuts and pinion yoke nuts immediately came to mind upon purchase. So after work I tried it out on my Deuce. I already have my trusty Ken-Tool wrench so I wanted to see how this unit compares. Due to the insane gear ratio, torquing or loosening a lug nut is like turning the handle on a pencil sharpener.

When I use the Ken-Tool wrench I only use the small drive bar (no pipe over it) when tightening and go until I hear the nuts "creak" on their seats. The gauge on the PowerDyne approached the 600 mark before the nut popped. I didn't like the shock load it put on the unit when the nut popped so if I use it again I will loosen them all the with Ken-Tool.

Overall opinion: I'm pretty fast with the Ken-Tool and it doesn't take up alot of storage space and fits in my bag in the driver side running board toolbox. The PowerDyne unit takes up more space and still needs a 3/4" drive extension if you want to use the crank handle for doing lug nuts. A huge plus for the PowerDyne however is I noticed that in both directions I did not need a jackstand for stability and I'm not juggling and resetting the position of drive bars, reaction bars, pipes etc. as with the Ken-Tool. Its much less combersome. You also don't have to work too hard either. The other huge plus for this thing is that it has a torque gauge. Most people only have a 1/2" drive click type torque wrench in their box so this is great for torquing those larger misc. fasteners without having to buy a $$$ torque wrench.

In terms of price I don't know what the Gov't acquisition cost was/is but I'd guess at least $1,500-1,700 and more. The three 12pt. sockets alone retail for $38, $39, and $50 respectively. The 12 point reaction bar box wrench retails for about $110.

Enjoy the pics!!

Attachments

-

60.6 KB Views: 50

-

87.4 KB Views: 63

-

60.5 KB Views: 54

-

65.4 KB Views: 52

-

56.9 KB Views: 49

-

51.3 KB Views: 47

-

88.5 KB Views: 57

-

79.6 KB Views: 49

-

76.9 KB Views: 47

-

93.4 KB Views: 48