martinv

Member

- 50

- 58

- 18

- Location

- Glyndon MN

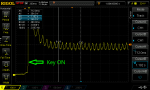

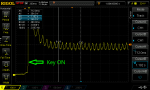

Today I decided to try a 'relative compression test' on the M35A2. This method uses a current probe on the battery line and measures current peaks caused by the compression of each cylinder. There should be 1 peak for each cylinder, then the pattern will repeat as long as you are cranking the engine.

Initially there is a very large (and expected) current spike. Shortly after the waveform stabilizes and this is the area to analyze.

Note: Fuel turned off so the engine wouldn't start during the test.

Here is my full waveform including just over 2 seconds of cranking:

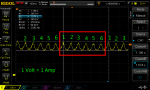

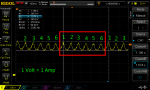

And here is a zoomed in view showing each cylinder number 1-6:

Which cylinder is actually #1 cannot be determined without some other method of triggering, but the goal is to look for a pattern. If every 4th and 5th peak was very low, this would indicate 2 sequential (in the firing order) cylinders have low compression.

I don't have much experience analyzing this method but it appears my engine is fairly consistent. This means all are good, bad or OK. A real compression test on 1 cylinder would tell which is the case. This seems like another good thing have as a baseline, so when you have a problem you can compare to a known previous state. I already had the test equipment available as I do electronics as a job and hobby. However this test could be done with the a very 'low end' scope and current probe since the frequency of the waveform is so low.

For comparison I may look at the voltage waveform at the starter to see if that gives a usable result. If it does, the current probe would not be needed, but I've heard the voltage method is not as clean of a waveform..

Finally here is the current clamp on the positive battery line:

Equipment:

Oscilloscope: RIGOL DS1054Z. (overkill for this job but I already had it)

Current Probe: Hantek CC-650 (Note: There may be a cheaper option. The minimum specs would be something like AC/DC capable, 500A and 1 kHz frequency response)

UPDATE (8/3/19):

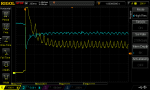

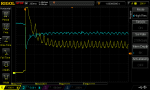

I added a voltage probe connected to the "+" battery line and re-ran the test. Basically the voltage waveform is not as useful due to 'noise' and lower peak to peak amplitude but you can still see the pattern. Also note the the voltage level is inverse from current. Each minimum occurs during maximum compression.

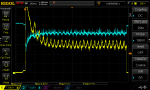

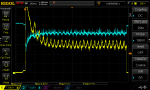

Using an acquire mode that reduces bandwidth and/or averages samples cleaned up the waveform. My scope calls this "High Res" mode: The waveform below is using the "normal" mode. Notice the high frequency noise:

Initially there is a very large (and expected) current spike. Shortly after the waveform stabilizes and this is the area to analyze.

Note: Fuel turned off so the engine wouldn't start during the test.

Here is my full waveform including just over 2 seconds of cranking:

And here is a zoomed in view showing each cylinder number 1-6:

Which cylinder is actually #1 cannot be determined without some other method of triggering, but the goal is to look for a pattern. If every 4th and 5th peak was very low, this would indicate 2 sequential (in the firing order) cylinders have low compression.

I don't have much experience analyzing this method but it appears my engine is fairly consistent. This means all are good, bad or OK. A real compression test on 1 cylinder would tell which is the case. This seems like another good thing have as a baseline, so when you have a problem you can compare to a known previous state. I already had the test equipment available as I do electronics as a job and hobby. However this test could be done with the a very 'low end' scope and current probe since the frequency of the waveform is so low.

For comparison I may look at the voltage waveform at the starter to see if that gives a usable result. If it does, the current probe would not be needed, but I've heard the voltage method is not as clean of a waveform..

Finally here is the current clamp on the positive battery line:

Equipment:

Oscilloscope: RIGOL DS1054Z. (overkill for this job but I already had it)

Current Probe: Hantek CC-650 (Note: There may be a cheaper option. The minimum specs would be something like AC/DC capable, 500A and 1 kHz frequency response)

UPDATE (8/3/19):

I added a voltage probe connected to the "+" battery line and re-ran the test. Basically the voltage waveform is not as useful due to 'noise' and lower peak to peak amplitude but you can still see the pattern. Also note the the voltage level is inverse from current. Each minimum occurs during maximum compression.

Using an acquire mode that reduces bandwidth and/or averages samples cleaned up the waveform. My scope calls this "High Res" mode: The waveform below is using the "normal" mode. Notice the high frequency noise:

Last edited: