MDSA

Member

- 705

- 12

- 18

- Location

- Valdese, NC

Checked the brakes on the Deuce using T M 9 - 2 3 2 0 - 2 0 9 - 2 0 - 3 - 2. No real problems till I came to the wheel bearing adjustment. This TM says:

w h e e l s h o u l d h a v e v e r y l i t t l e w o b b l e .

Seemed a little too subjective to me so I searched the threads and found one that said to use a torque wrench. Don't have a wheel bearing socket so can't torque it. I only have a pipe wrench.

I did what my TM says and have NO wobble. So is it too tight?

Any advice besides finding a wheel bearing socket? (which i may have to do)

Thank you

1 . C h e c k b r a k e a d j u s t m e n t . R e f e r t o p a r a 1 3 - 9 .

2 . R e p l a c e f r o n t w h e e l . R e f e r t o T M 9 - 2 3 2 0 - 2 0 9 - 1 0 .

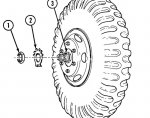

3 . W h i l e t u r n i n g w h e e l ( 1 ) a n d u s i n g w h e e l b e a r i n g n u t w r e n c h , t i g h t e n a d j u s t i n g

n u t ( 2 ) u n t i l w h e e l b i n d s .

4 . U s i n g w h e e l b e a r i n g n u t w r e n c h , b a c k o f f a d j u s t i n g n u t ( 2 ) 1 / 8 t u r n .

5 . P u t o n e h a n d o n b o t t o m a n d o n e h a n d o n t o p o f w h e e l ( 1 ) . P u s h w i t h o n e h a n d

a n d p u l l w i t h t h e o t h e r h a n d . I f w h e e l b e a r i n g ( 3 ) i s a d j u s t e d c o r r e c t l y ,

2 . R e p l a c e f r o n t w h e e l . R e f e r t o T M 9 - 2 3 2 0 - 2 0 9 - 1 0 .

3 . W h i l e t u r n i n g w h e e l ( 1 ) a n d u s i n g w h e e l b e a r i n g n u t w r e n c h , t i g h t e n a d j u s t i n g

n u t ( 2 ) u n t i l w h e e l b i n d s .

4 . U s i n g w h e e l b e a r i n g n u t w r e n c h , b a c k o f f a d j u s t i n g n u t ( 2 ) 1 / 8 t u r n .

5 . P u t o n e h a n d o n b o t t o m a n d o n e h a n d o n t o p o f w h e e l ( 1 ) . P u s h w i t h o n e h a n d

a n d p u l l w i t h t h e o t h e r h a n d . I f w h e e l b e a r i n g ( 3 ) i s a d j u s t e d c o r r e c t l y ,

w h e e l s h o u l d h a v e v e r y l i t t l e w o b b l e .

Seemed a little too subjective to me so I searched the threads and found one that said to use a torque wrench. Don't have a wheel bearing socket so can't torque it. I only have a pipe wrench.

I did what my TM says and have NO wobble. So is it too tight?

Any advice besides finding a wheel bearing socket? (which i may have to do)

Thank you