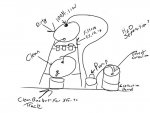

Ok, I sketched out a quick setup for a relatively low cost wmo system that I would like some thoughts on.

I have an large heated garage to put this in and since it is always 65+ I think that preheating can can wait until later (maybe)

The design is relatively open with room for easy upgrades in the future, such as moving from gravity fed to pumped filtering and such.

Basically I would like to do my collection with a 55 gallon drum and pump, using a screen mesh to avoid the big chunks. Then pump that to a 55gallon drum on a 10ft stand, plumb a drain off the raised barrel to run through a series of filters, to end in yet another barrel. The filtered oil could then be moved to the truck with by pump or by bucket.

Filters could go like this 25 -> Racor 6120R with 30micron filter -> 10 micron -> 1 micron

My thinking of putting the 25 before the Racor 30 is to extend the life of the more expensive filter while still getting the water separation. I may also add a water blocking filter after the final 1 micron(?)

I dunno this might be to much restriction to get away with doing a gravity feed, but adding a pump wouldn't be that hard, but the way I see it the need for additional fittings and pressure gauges greatly increases the cost.

Also, anyone have any idea on a way to rig up 2-3 bag filters with housings? Perhaps a cheap source or thoughts on making a housing with PVC?

Basically I want to try to build a budget system that is expandable for a couple reasons. 1) I am cheap 2) I can 3) if it works I can post the plans and hopefully other people can get in on it that are scared off by the perceived high costs of setup.

I have an large heated garage to put this in and since it is always 65+ I think that preheating can can wait until later (maybe)

The design is relatively open with room for easy upgrades in the future, such as moving from gravity fed to pumped filtering and such.

Basically I would like to do my collection with a 55 gallon drum and pump, using a screen mesh to avoid the big chunks. Then pump that to a 55gallon drum on a 10ft stand, plumb a drain off the raised barrel to run through a series of filters, to end in yet another barrel. The filtered oil could then be moved to the truck with by pump or by bucket.

Filters could go like this 25 -> Racor 6120R with 30micron filter -> 10 micron -> 1 micron

My thinking of putting the 25 before the Racor 30 is to extend the life of the more expensive filter while still getting the water separation. I may also add a water blocking filter after the final 1 micron(?)

I dunno this might be to much restriction to get away with doing a gravity feed, but adding a pump wouldn't be that hard, but the way I see it the need for additional fittings and pressure gauges greatly increases the cost.

Also, anyone have any idea on a way to rig up 2-3 bag filters with housings? Perhaps a cheap source or thoughts on making a housing with PVC?

Basically I want to try to build a budget system that is expandable for a couple reasons. 1) I am cheap 2) I can 3) if it works I can post the plans and hopefully other people can get in on it that are scared off by the perceived high costs of setup.

Attachments

-

37.9 KB Views: 67