- 1,630

- 728

- 113

- Location

- Central NY

Got quite the surprise when I pulled the siezed rollers for bearing service... and to paint inside of roller housing following RAEME sus-tow mod.

Even though the rollers are very heavy, come to find out that they are hollow and that the space between the top and bottom roller bearings (and would assume the same for horiz' ones) is full of grease. Maybe over two tubes full!... each roller! That's upwards of 9 tubes wasted, just to fill void before pressure can build and then vent to outside as normally seen when you grease a fitting.

To me, this is a waste and unacceptable. I am looking at making a communication sleeve to go between the bearing outer races to cut down on the volume of grease reqd before expulsion from bronze washers is seen - thus knowing full greasing of bearing. (a la small trolley/lawn mower wheel etc.)

Also looks like there was an ineffective seal next to the bronze thrust washers allowing water to pool and corrode the bottom bearing.

I also need another bronze washer if any one has a lead on spares. (Jeff - still stripping those 816's?)

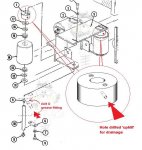

(.... oh yeah - do you really need a pic!) The TM for servicing rollers shows an exploded diag of components.

Even though the rollers are very heavy, come to find out that they are hollow and that the space between the top and bottom roller bearings (and would assume the same for horiz' ones) is full of grease. Maybe over two tubes full!... each roller! That's upwards of 9 tubes wasted, just to fill void before pressure can build and then vent to outside as normally seen when you grease a fitting.

To me, this is a waste and unacceptable. I am looking at making a communication sleeve to go between the bearing outer races to cut down on the volume of grease reqd before expulsion from bronze washers is seen - thus knowing full greasing of bearing. (a la small trolley/lawn mower wheel etc.)

Also looks like there was an ineffective seal next to the bronze thrust washers allowing water to pool and corrode the bottom bearing.

I also need another bronze washer if any one has a lead on spares. (Jeff - still stripping those 816's?)

(.... oh yeah - do you really need a pic!) The TM for servicing rollers shows an exploded diag of components.