dikwks

Member

- 237

- 2

- 18

- Location

- Suffolk VA

Hello all. I intended to post this up later (first run is not complete), but got dared and couldn't resist.

Here's the background: I bought some surplus tent heaters and was interested in burning WMO in them. I already have a filtration set up working for other reasons so I already had some filtered oil available. The TM that came with the heaters said specifically not to use WMO, but I thought about how useful it might be if I could use WMO, and decided to do it anyway. I mixed up a batch of oil thinned with gasoline at a ratio of about 1 gas to 2 WMO. That ratio worked out to about the same viscosity as diesel. I usually thin it out at a ratio of 1 to 4. It worked just fine in the heater, but what got me was how much extra crud ended up in the bottom of the container.

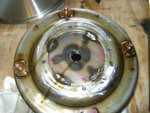

My WMO processing system consists of a settling tank for dirty oil, a 4 stage filtration system, and a cleaned oil storage tank. The oil sits for at least a month in each tank, and I drain off water from them both on a regular basis, so i'm thinking that it's all good, right? The heater mix thing made me a little less sure. So, what to do? I knew that a centrifuge would get the oil cleaner, but the stuff available commercially seemed a bit pricey. So I decided to build one. There is a vid on youtube about a centrifuge made from a torque converter. The torque converter seemed like a good way to overcome the biggest obstacle, a balanced circular form that would hold oil with a rim at the top. So, here we go!! I used materials that have been sitting around literally for decades and now have about $100 tied up in it so far. The 'fuge is a torque converter, the catch basin is a big cooking pot, and the bearings and motor are collected scrap. The biggest expense was fasteners and the wood for the lower half of the stand.

What you see in the pix is a feed tank on the left, the centrifuge in the middle, and the clean tank on the right. The last picture is from spinning up only about 10 gallons of a 50 gallon test run. Testing has been interrupted by knee surgery today, but tomorrow is looking pretty good. Doesn't take much effort to babysit a spinning motor.

Enjoy the pix, and feel free to ask questions. The thing to keep in mind is if I can do it with the limited resources I have, so can you.

Here's the background: I bought some surplus tent heaters and was interested in burning WMO in them. I already have a filtration set up working for other reasons so I already had some filtered oil available. The TM that came with the heaters said specifically not to use WMO, but I thought about how useful it might be if I could use WMO, and decided to do it anyway. I mixed up a batch of oil thinned with gasoline at a ratio of about 1 gas to 2 WMO. That ratio worked out to about the same viscosity as diesel. I usually thin it out at a ratio of 1 to 4. It worked just fine in the heater, but what got me was how much extra crud ended up in the bottom of the container.

My WMO processing system consists of a settling tank for dirty oil, a 4 stage filtration system, and a cleaned oil storage tank. The oil sits for at least a month in each tank, and I drain off water from them both on a regular basis, so i'm thinking that it's all good, right? The heater mix thing made me a little less sure. So, what to do? I knew that a centrifuge would get the oil cleaner, but the stuff available commercially seemed a bit pricey. So I decided to build one. There is a vid on youtube about a centrifuge made from a torque converter. The torque converter seemed like a good way to overcome the biggest obstacle, a balanced circular form that would hold oil with a rim at the top. So, here we go!! I used materials that have been sitting around literally for decades and now have about $100 tied up in it so far. The 'fuge is a torque converter, the catch basin is a big cooking pot, and the bearings and motor are collected scrap. The biggest expense was fasteners and the wood for the lower half of the stand.

What you see in the pix is a feed tank on the left, the centrifuge in the middle, and the clean tank on the right. The last picture is from spinning up only about 10 gallons of a 50 gallon test run. Testing has been interrupted by knee surgery today, but tomorrow is looking pretty good. Doesn't take much effort to babysit a spinning motor.

Enjoy the pix, and feel free to ask questions. The thing to keep in mind is if I can do it with the limited resources I have, so can you.

Attachments

-

83 KB Views: 293

-

79.3 KB Views: 251

-

81.3 KB Views: 264

-

85.5 KB Views: 245

-

54.4 KB Views: 248

-

82.5 KB Views: 252

-

78.8 KB Views: 288

-

78.3 KB Views: 341

-

87.8 KB Views: 251