ProgDrummer79

New member

- 14

- 0

- 1

- Location

- Trout Run/PA

So, with the weather breaking, I'm planning on taking my truck to a shop to flip the hubs and install singles all around. I'll be taking it to a truck shop that has the facility and tools to do it.

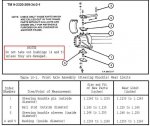

My question is, if you were going to take your truck to a reputable truck shop to do this, what other work would you have them do? I'm new to deuces, so I'm still doing lots of research, but I was thinking about having them "refurbish" the axles with new seals and whatnot. I still need to figure out what seals would be needed. But is there anything else you would think would be good to have them do while they're rippin' and tearin' under there. I'm looking for just a few odds and ends that, even if not worn out, would be a good idea to change or update while they have it there. I'm not made of money, so I'm limited, but would be willing to spend a few extra bux on some little items. What do ya think?

My question is, if you were going to take your truck to a reputable truck shop to do this, what other work would you have them do? I'm new to deuces, so I'm still doing lots of research, but I was thinking about having them "refurbish" the axles with new seals and whatnot. I still need to figure out what seals would be needed. But is there anything else you would think would be good to have them do while they're rippin' and tearin' under there. I'm looking for just a few odds and ends that, even if not worn out, would be a good idea to change or update while they have it there. I'm not made of money, so I'm limited, but would be willing to spend a few extra bux on some little items. What do ya think?