74M35A2

Well-known member

- 4,145

- 330

- 83

- Location

- Livonia, MI

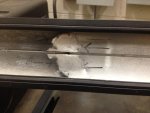

I want a one piece double row LED light bar to go across the windshield top of my M925A2. Nobody I could easily find makes them in 74" or so. Their prices have fallen on eBay, so I bought two 54" ones, and disassembled them. Welding the housing together, then having a one piece lens made. The light assemblies are modular inside, so it is easy to just remove from one and add to another in blocks of 4. Pics to follow, but for $100 each, we'll see what happens.

I was surprised the end mounting brackets were metal. I think with that much span, I will probably place a brace in the center also. For tree protection, I'm considering to add a flip down cover like the 6 lamp halogen bar has, or simply make the bar quick detachable.

I was surprised the end mounting brackets were metal. I think with that much span, I will probably place a brace in the center also. For tree protection, I'm considering to add a flip down cover like the 6 lamp halogen bar has, or simply make the bar quick detachable.