SteveKuhn

New member

- 1,227

- 4

- 0

- Location

- Hasbrouck Heights NJ

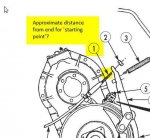

I need to replace the nut (2) on transfer case end end of the parking brake cable. I know the TM shows a unique nut but I'd like to try to replace it with something fairly standard. None from my odd collection fit.

Can someone provide the size and thread pitch (1)?

Also, the TM suggests that the adjustment should begin from a point marked on the cable. Mine is old and there's no mark. About how far in should that be?

Thanks.

Steve

Can someone provide the size and thread pitch (1)?

Also, the TM suggests that the adjustment should begin from a point marked on the cable. Mine is old and there's no mark. About how far in should that be?

Thanks.

Steve

Attachments

-

30 KB Views: 51