Just getting back to this CUCV after being gone TDY all last week...

As I mentioned, I had stopped at the Barber Shop after work on the first test drive day into work. When I went to leave it the starter was engaging but would not engage the flywheel do to chipped and wore down teeth. So replacing the flexplate flywheel was in order.

For anyone comptemplating a flywheel change, this was much easier that I thought it would be and I did not have to completely remove the the THM400/NP208.

Disconnect the battery cables

Remove the flywheel inspection cover and torque converter bolts

Remove the 6 bell housing bolts (and I slightly bent the starter shield bolt tab to clear the trans)

Reinstall 2 or 4 new bolts that are approximately 4" long in the lower holes to support the bell housing (I used 2)

I jacked the engine up and placed a large jack stand under the pan to support the engine and less the bind and realignment upon engine/bell housing split

remove the differential ends of both drive shafts and tape the caps so they don't fall off

disconnect the linkage by removing the clip and pull it out of transmission end

disconnect the two cooler lines from the transmission

I put small jack stands on a little 4 wheel cart I made with a bottle jack in the center on dunage and jacked up the crossmember enough to support it while I removed the 4 crossmember bolts and lowered it to the jackstands

then using a large prybar I split the bell housing from the engine enough to gain access to the flexplate/flywheel bolts. Because it was on the cart it just rolled back on its own.

Use a long prybar to lock the flywheel enough to break the torque of the mounting bolts or a flywheel tool which I tryed using too, but this one was a borrowed and well used POS from HF

After I figured out it had a bent tab and bent it back with a hammer it worked good upon tightening the bolts on the new flexplate.

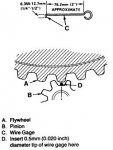

If you are unfamiliar with the tool here is what they look like:

I did not like the looks of the starter alignment so I put the start shim back in and I'm unable to pull the bendix with a pick to check it. so I'll pull the starter today and see if I can move once its out. I did notice the front support bracket was cut off so it was probably done by whomever installed the starter to gain access for clearence rather than just removing it so I'll have to figure out some way to support the front end too.

I also ordered a WIX 24770 filter base and using the posted pdf of compatible filters I also ordered a WIX 33426 filter. The thread is correct but it is not the correct diameter to seal with the mount. When I get to installing this and get a correct filter I'll do this in a seperate post.