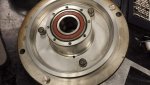

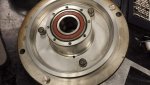

Alright, here is my progress so far. I have completely disassembled the clutch, keeping in mind its function as I examined the parts. I am not yet certain what would be causing the rattling. It may be some of the bushings/spacers that I found... they were a bit loose, but I can't imagine they would make a loud clanging noise. One of the very first things I found was RUST.

It seems like moisture collected in the clutch, maybe from someone fording the vehicle, I'm not entirely sure. Some of the rust was on non-critical components, but there was rust on the thrust plate and cap. The faces on these, and the clutch disc, were also "too smooth".

Most of the work I had performed thus far was rust removal and using some scotch-brite on the thrust faces. When I was first taking the clutch apart, I noticed some grease under the seal plug, which housed a nut which kept the assembly together. At first I didn't think anything of it, until I removed the thrust plate and found hard, grimy grease caked underneath.

This is problematic because there was a small channel that leads from the rear of the thrust plate to the seal plug. The center shaft is hollow, which feeds air into the are under the seal plug, which then presses on the back of the thrust plate. I found the rust and grease made it very difficult for the thrust plate to move so I used a strong degreaser to clean the housing (the part with the 3 studs). I also used degreaser and a swab in all the air channels, most of which were clogged with grease.

At this point, I need to get some Loctite for the thrust cap screws and then reassemble. While reading the PDF from Evans, the section on rebuilding says nothing about greasing any component while reassembling. My guess is someone mistakenly put grease into the clutch which caused issues with the thrust plate... and possibly the rattling noise. Only after reassembling will I know if simply cleaning it and etching the faces improved its performance.