Justin8321

New member

- 8

- 0

- 0

- Location

- Deltona FL

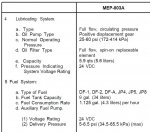

Just purchased a 2006 Mep-803a with 2500 hours on the unit. I changed the oil right when I picked up the getset and changed the filter as well with rottela t5 synthetic blend 15w-40 and a wix filter 51374. When the unit is cold I get a great 50 psi and as soon as the unit warms up to temp it goes down to about 21-22 psi. I can’t figure out why this could be. Any suggestions?

Last edited: