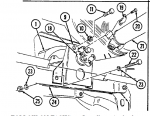

My front diff had a dental problem: it lost some teeth  I've got what is claimed to be brand new 2.56 ratio one, and it looks at least freshly rebuilt. To take out the old one and put in the new I need to remove the pinion nut to take off the yoke in order to pull it through the rear diff mount. According to TM 9-3220-280-34 section 9-5 "differential replacement", I should measure the torque to rotate the new diff via the pinion nut, take off the lock nut, discard it, put the diff back in the truck, and use a new pinion nut and tighten is slowly under the torque to turn the diff is 2 ft-lb higher than it was when I took the nut off.

I've got what is claimed to be brand new 2.56 ratio one, and it looks at least freshly rebuilt. To take out the old one and put in the new I need to remove the pinion nut to take off the yoke in order to pull it through the rear diff mount. According to TM 9-3220-280-34 section 9-5 "differential replacement", I should measure the torque to rotate the new diff via the pinion nut, take off the lock nut, discard it, put the diff back in the truck, and use a new pinion nut and tighten is slowly under the torque to turn the diff is 2 ft-lb higher than it was when I took the nut off.

The new diff has no oil in, probably never has, and the output flanges are off, and feels like it may be just the tiniest bit notchy when I rotate from the yoke, but again... no oil. I can follow the instructions, but have also read that I should just mark exactly where the current lock nut is, and put it on exactly that amount, maybe a tiny bit more.

Who's done this before and can tell me the best path?

Thanks,

Jordan

The new diff has no oil in, probably never has, and the output flanges are off, and feels like it may be just the tiniest bit notchy when I rotate from the yoke, but again... no oil. I can follow the instructions, but have also read that I should just mark exactly where the current lock nut is, and put it on exactly that amount, maybe a tiny bit more.

Who's done this before and can tell me the best path?

Thanks,

Jordan