JasonS

Well-known member

- 1,650

- 144

- 63

- Location

- Eastern SD

Steel Soldiers now has a few new forums, read more about it at: New Munitions Forums!

The cylinder is off of a 5-ton. The ball pin is from a 5-ton; turned down and shortened to fit the deuce. A local shop fabricated the steering arm (4140 prehard). The cylinder end is from a Ford tractor. The hoses/ fittings came from NAPA.Where did you get that arm and link from ? Also who made that front spring anchor pin for you and where did you buy that hydraulic ram ?

At least forces are better distributed, that way.Easier to steer than just the hf54 box upgrade?

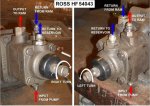

Hi, I want to do this. I came across a used RossH54 with cylinder assist valve. Looks like the bottom port on the box assembly is pressure in from the pump and the rear port of three on valve [towards box input shaft] is the return port. Is this correct? Thanks, Paul

Hi, I want to do this. I came across a used RossH54 with cylinder assist valve. Looks like the bottom port on the box assembly is pressure in from the pump and the rear port of three on valve [towards box input shaft] is the return port. Is this correct?

See it here....I followed the blue lines with braid cover to the bulkhead fittings. Then to the ram. So the top most of the three ports is either return or pressure in. I dont see any markings at the ports on my unit.

Guess I should have done the same - instead of re-posting my own files...Thanks, I have been searching for exactly this. Paul

Photo of setup . Front axle is f106 hybrid with 5 ton knuckles built to my specs by Gearhart Engineering. Uses 2 1/2 ton hubs modified to take the 5 ton spindle and bearings.Thanks again, I Googled it every which way but loose but no luck. My truck is a Mud Truck with a double ended cylinder up front. Hydro assist and I am keeping the tie rod so the set up is tricky.

Yes and yes...... could a steering arm for the left side be bolted on the right side and the ball stud removed and a suitable rod end be used to connect it to the 5 ton steering ram?

In the Marine Corp, a little duct tape and bailing wire is all you need for 99% of all repairs !Thank-you! "Sir gringeltaube", your experience is extremely appreciated. The results of your modifications are most impressive!

When I was in the Army many years ago we had a little saying that kind of explains some of the "less than professional" maintenance seen on some of these 40-50 year vehicles. "Measure with a micrometer, mark it with chalk, cut it with an ax and paint to cover up your mistakes; and if it don't run, Chrome it!" Funny but too close to the truth at times. Especially because I worked on army aircraft, not in the motor pool.

We get it, advertisements are annoying!

Sure, ad-blocking software does a great job at blocking ads, but it also blocks useful features of our website like our supporting vendors. Their ads help keep Steel Soldiers going. Please consider disabling your ad blockers for the site. Thanks!