here's a bunch of questions I encountered very quickly while changing the first tire.

first of all,

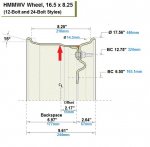

In preparing to install new tires, I found out that I have the older style 12 bolt rims.

As I understand it they have a tendency to not align well and so three centering washers(per wheel) need to be installed so that the balance is not WAY off.

the military apparently did not bother to use the washers(since they were an AM general after thought) so my truck bounces down the road at certain speeds.

The newer rims(which my spare tire has) have an "alignment hole".

How precisely does the hole need to be lined up?

It seems to me that the same problem can occur as with the older style if assembled without the centering washers.

Am I missing something?

Also, any trick to aligning the old 12 bolt rims without using the centering washers?

or should I just get a set of newer style rims?

Any benefit to getting 24 bolt(even or tandem E-rated) rims other than gaining weight capacity?

do they align more easily?

If the o-rings look ok is there any problem with reusing them?

I just changed out the tire on a rim that had what looks like red gasket making gunk on the black o-ring, is that an acceptable practice or not recommended? I've read that applying grease to the o-ring is recommended.

first of all,

In preparing to install new tires, I found out that I have the older style 12 bolt rims.

As I understand it they have a tendency to not align well and so three centering washers(per wheel) need to be installed so that the balance is not WAY off.

the military apparently did not bother to use the washers(since they were an AM general after thought) so my truck bounces down the road at certain speeds.

The newer rims(which my spare tire has) have an "alignment hole".

How precisely does the hole need to be lined up?

It seems to me that the same problem can occur as with the older style if assembled without the centering washers.

Am I missing something?

Also, any trick to aligning the old 12 bolt rims without using the centering washers?

or should I just get a set of newer style rims?

Any benefit to getting 24 bolt(even or tandem E-rated) rims other than gaining weight capacity?

do they align more easily?

If the o-rings look ok is there any problem with reusing them?

I just changed out the tire on a rim that had what looks like red gasket making gunk on the black o-ring, is that an acceptable practice or not recommended? I've read that applying grease to the o-ring is recommended.

Last edited: