-

Steel Soldiers now has a few new forums, read more about it at: New Munitions Forums!

Does Cat C7 have major problems that plagued legacy Engines of FMTV/LMTV family.

- Thread starter GENX

- Start date

More options

Who Replied?Ronmar

Well-known member

- 4,112

- 7,918

- 113

- Location

- Port angeles wa

Little late to ask now isn’t it

No oil line of death, thats a 3116 thing. I think they worked the bugs mostly out of the HEUI system by the time they got to the C7. The 3126s would occasionally fracture a HP oil line, and they also made some improvements to secondary oil filtration in the HEUI system. Things I have not heard issues about on the C7…

I believe The air compressor and hydraulic PS pump installation is virtually the same across all 3 LMTV engines. Issues with them are not a problem with that installation, but when issues arise with the secondary rear support bracket that fail to properly support all that overhung weight. check your brackets and fasteners. Other issues like wheel and driveshaft balance are also probably causative factors in front case cracks when the rear compressor bracket comes loose, fails or some knucklehead in the motor-pool flat fails to re-install it…

Good luck on your new truck…

No oil line of death, thats a 3116 thing. I think they worked the bugs mostly out of the HEUI system by the time they got to the C7. The 3126s would occasionally fracture a HP oil line, and they also made some improvements to secondary oil filtration in the HEUI system. Things I have not heard issues about on the C7…

I believe The air compressor and hydraulic PS pump installation is virtually the same across all 3 LMTV engines. Issues with them are not a problem with that installation, but when issues arise with the secondary rear support bracket that fail to properly support all that overhung weight. check your brackets and fasteners. Other issues like wheel and driveshaft balance are also probably causative factors in front case cracks when the rear compressor bracket comes loose, fails or some knucklehead in the motor-pool flat fails to re-install it…

Good luck on your new truck…

- 2,321

- 5,772

- 113

- Location

- Portland, OR

The C7 (in school bus and other higher mileage applications) is known for wanting very clean oil to the HEUI pump and cat supplies all replacement HEUI pumps with a new oil feed line that includes a serviceable cartridge filter. If you do some searching here on the forum I recently posted the part numbers to upgrade just the feed line since most of our FMVT engines are such low mileage that it's worth it to protect the HEUI pump IMO. It's about $200 in parts.

You should check that all your brackets for the compressor and hydraulic pump and alternator and whatever else is hanging off the drivetrain has the proper Nord Lock washers keeping it from backing out.

You should check that all your brackets for the compressor and hydraulic pump and alternator and whatever else is hanging off the drivetrain has the proper Nord Lock washers keeping it from backing out.

I have seen that there is a housing cover that should also be checked for trueness between your oil cooler and oil filter housing.The C7 (in school bus and other higher mileage applications) is known for wanting very clean oil to the HEUI pump and cat supplies all replacement HEUI pumps with a new oil feed line that includes a serviceable cartridge filter. If you do some searching here on the forum I recently posted the part numbers to upgrade just the feed line since most of our FMVT engines are such low mileage that it's worth it to protect the HEUI pump IMO. It's about $200 in parts.

You should check that all your brackets for the compressor and hydraulic pump and alternator and whatever else is hanging off the drivetrain has the proper Nord Lock washers keeping it from backing out.

Ronmar

Well-known member

- 4,112

- 7,918

- 113

- Location

- Port angeles wa

The oil cooler fitment also applies to the 3116 and 3126. Of course if it is not correct it will tend to leak… Not as big a show-stopper as driveshaft vibrations shaking the engine accessories to failure…

Agree. That's what I am trying to address first priority when I get the truck.. all the "show stoppers"The oil cooler fitment also applies to the 3116 and 3126. Of course if it is not correct it will tend to leak… Not as big a show-stopper as driveshaft vibrations shaking the engine accessories to failure…

In regards to driveshafts being balanced. This seems to be a huge issue especially Hawaiian loaded trucks.

I had watched a video on a vehicle that had axles propping tires up off the ground, as the engine was exercised and trans engaged it brought the wheels up to spinning at an equivalent top highway speed; there was a glass of water fitted with an L bracket and a high strength magnet to inspect the displacement of the water (shaking). Then the drive shaft was lightly touched with chalk. Then the chalk was inspected (after shutting engine off of course and the area that had the deepest chalk mark was equipped with two pipe clamps. The pipe clamps were spread out over multiple inspections to see which combination imparted the most balanced calming effect to the water.

This seemed very unscientific to me but I was going to research more into checking for true driveshafts. I ordered a drive shaft separate tool and was going to pull it and find someone to check it for runout at some machine shop and go from there.

I had watched a video on a vehicle that had axles propping tires up off the ground, as the engine was exercised and trans engaged it brought the wheels up to spinning at an equivalent top highway speed; there was a glass of water fitted with an L bracket and a high strength magnet to inspect the displacement of the water (shaking). Then the drive shaft was lightly touched with chalk. Then the chalk was inspected (after shutting engine off of course and the area that had the deepest chalk mark was equipped with two pipe clamps. The pipe clamps were spread out over multiple inspections to see which combination imparted the most balanced calming effect to the water.

This seemed very unscientific to me but I was going to research more into checking for true driveshafts. I ordered a drive shaft separate tool and was going to pull it and find someone to check it for runout at some machine shop and go from there.

Ronmar

Well-known member

- 4,112

- 7,918

- 113

- Location

- Port angeles wa

Any large truck shop should be able to point you to someone who can service the driveshafts. Measuring installed vibration works, it is just tedious and time consuming. You also need to be able to set the structure being balanced up in such a way that it allows movement so you can measure the displacement. Then you need a way to consistently measure that displacement. I balanced a slow speed diesel generator this way by setting the whole frame on pipe rollers then measuring the vibration displacement with a dial indicator, while spining the crank and flywheel with an electric motor… then it was a matter of trial and error with clay weights. Like I said tedious and time consumingIn regards to driveshafts being balanced. This seems to be a huge issue especially Hawaiian loaded trucks.

I had watched a video on a vehicle that had axles propping tires up off the ground, as the engine was exercised and trans engaged it brought the wheels up to spinning at an equivalent top highway speed; there was a glass of water fitted with an L bracket and a high strength magnet to inspect the displacement of the water (shaking). Then the drive shaft was lightly touched with chalk. Then the chalk was inspected (after shutting engine off of course and the area that had the deepest chalk mark was equipped with two pipe clamps. The pipe clamps were spread out over multiple inspections to see which combination imparted the most balanced calming effect to the water.

This seemed very unscientific to me but I was going to research more into checking for true driveshafts. I ordered a drive shaft separate tool and was going to pull it and find someone to check it for runout at some machine shop and go from there.

I would have to be pretty desperate to try and do an LMTV driveshaft, the setup would be difficult and insuring other forces were not skewing the results is problimatic. It is easy enough to test hinging while on the truck, but since these trucks have such steep driveshaft angles, the shafts really need to be perfect…

coachgeo

Well-known member

- 5,155

- 3,477

- 113

- Location

- North of Cincy OH

any driveline shop that does a good bit of work with Big Rigs can check your driveshafts. These driveshafts happen to be made up of regular heavyduty truck parts. I'd say grab the yellow pages and look for one and call them.... but then I'd sound really old lol. Go by your local truck stop with a small shop and ask them for the local place they send driveshafts over too for repairs will be your best hint on where to take them.In regards to driveshafts being balanced. ....

- 2,321

- 5,772

- 113

- Location

- Portland, OR

Military trucks don't typically have enough miles on them to exhibit the oil cooler issues. That is seen in higher mileage applications like school busses and over the road trucks, etc.

My A1R seems to have excellent driveline balance with the high-pinion rear axle. Once my 2008 tires rounded back out from over a decade of mostly sitting my ride is very nice actually. The usual driveline problem is that some PVT Snuffy type has taken the driveshaft out of the truck and clocked them on the slip yoke incorrectly during servicing. The pre-A1R 4x4 trucks have an absurd rear driveline angle and it's prone to hitting obstacles and being damaged by forklifts, etc.

As for service interval - any truck that's new to me I would recommend replacing the u-joints and having the driveshafts balanced if there is any question about it. Look to make sure the yokes are lined up with each other. Grease the slip yokes and check for any play in the splines, etc. They should have very little play.

My A1R seems to have excellent driveline balance with the high-pinion rear axle. Once my 2008 tires rounded back out from over a decade of mostly sitting my ride is very nice actually. The usual driveline problem is that some PVT Snuffy type has taken the driveshaft out of the truck and clocked them on the slip yoke incorrectly during servicing. The pre-A1R 4x4 trucks have an absurd rear driveline angle and it's prone to hitting obstacles and being damaged by forklifts, etc.

As for service interval - any truck that's new to me I would recommend replacing the u-joints and having the driveshafts balanced if there is any question about it. Look to make sure the yokes are lined up with each other. Grease the slip yokes and check for any play in the splines, etc. They should have very little play.

I have what appears to be an A1-(R) sort of... from what I can tell. But the alternator states 100Amp.

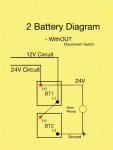

Expedition Portal member has an Acela M1078 for sale. Acela has put 2- Group 8D batteries on this truck, in lieu of the (4) 6TL batteries.

What are the known tried and true modifications one should be looking at to ensure survival of the batteries etc? My batteries are MFR May of this year, 4 6TL.

In studying the cold cranking amps of the 8D and the size they are very comparable to the 6TL but are quite a bit cheaper. The Owner put a NOCO charger on his and hooked it to the Solar and shorepower so that when boondocking it will supplement excess power diverted to the battery or when docked it maintains.

I have seen Sean Pilsner's HMMV Alternator swap vid. Got me to thinking that perhaps I should address this sooner than later. But I am not 100% clear where to start or what the pioneers on here have done to address the low output alternator to large battery bank power debacle. I am looking for input.

If I had a true "A1R" shouldn't the Alternator be 200A output?

How do I determine exactly what route to take and what's the best fix? This truck expressed a desire to be converted into an Expedition Camper, with Motobike carrier, ski locker and surfboard so it could run the gambit of cold to hot environments...

Expedition Portal member has an Acela M1078 for sale. Acela has put 2- Group 8D batteries on this truck, in lieu of the (4) 6TL batteries.

What are the known tried and true modifications one should be looking at to ensure survival of the batteries etc? My batteries are MFR May of this year, 4 6TL.

In studying the cold cranking amps of the 8D and the size they are very comparable to the 6TL but are quite a bit cheaper. The Owner put a NOCO charger on his and hooked it to the Solar and shorepower so that when boondocking it will supplement excess power diverted to the battery or when docked it maintains.

I have seen Sean Pilsner's HMMV Alternator swap vid. Got me to thinking that perhaps I should address this sooner than later. But I am not 100% clear where to start or what the pioneers on here have done to address the low output alternator to large battery bank power debacle. I am looking for input.

If I had a true "A1R" shouldn't the Alternator be 200A output?

How do I determine exactly what route to take and what's the best fix? This truck expressed a desire to be converted into an Expedition Camper, with Motobike carrier, ski locker and surfboard so it could run the gambit of cold to hot environments...

- 2,321

- 5,772

- 113

- Location

- Portland, OR

The A1R and A1P2 trucks have the 260A alternator. FMTV's went from 100 straight to 260. I believe there may have been a kit for a 200A unit offered back in the A0/A1 days but I've never seen one. Production units were 100 and later 260.

Other A1R features include the high-pinion rear axle, pintle hitch extendable receiver, WTEC 4 and matching transmission, front coil over shocks for armored cab upgrade, and air ride cab delete.

Other A1R features include the high-pinion rear axle, pintle hitch extendable receiver, WTEC 4 and matching transmission, front coil over shocks for armored cab upgrade, and air ride cab delete.

Third From Texas

Well-known member

- 2,812

- 6,621

- 113

- Location

- Corpus Christi Texas

ABSOLUTELY WITHOUT FAIL change to dual batteries with a 100a alt. Hell, I have the 260 alt and only run duals (the others are used as house batteries at the moment and only charge via shore power).I have what appears to be an A1-(R) sort of... from what I can tell. But the alternator states 100Amp.

Expedition Portal member has an Acela M1078 for sale. Acela has put 2- Group 8D batteries on this truck, in lieu of the (4) 6TL batteries.

What are the known tried and true modifications one should be looking at to ensure survival of the batteries etc? My batteries are MFR May of this year, 4 6TL.

In studying the cold cranking amps of the 8D and the size they are very comparable to the 6TL but are quite a bit cheaper. The Owner put a NOCO charger on his and hooked it to the Solar and shorepower so that when boondocking it will supplement excess power diverted to the battery or when docked it maintains.

I have seen Sean Pilsner's HMMV Alternator swap vid. Got me to thinking that perhaps I should address this sooner than later. But I am not 100% clear where to start or what the pioneers on here have done to address the low output alternator to large battery bank power debacle. I am looking for input.

If I had a true "A1R" shouldn't the Alternator be 200A output?

How do I determine exactly what route to take and what's the best fix? This truck expressed a desire to be converted into an Expedition Camper, with Motobike carrier, ski locker and surfboard so it could run the gambit of cold to hot environments...

It's a five minute mod and there are plenty of threads here to read up on it.

Last edited:

Third From Texas

Well-known member

- 2,812

- 6,621

- 113

- Location

- Corpus Christi Texas

I would say "drive it until the alt fails someday".How do I determine exactly what route to take and what's the best fix? This truck expressed a desire to be converted into an Expedition Camper, with Motobike carrier, ski locker and surfboard so it could run the gambit of cold to hot environments...

Then get you a heavy duty commercial civilian ~200a 24v alt. Ad a step down for the 12v stuff. /done

That will set you back a couple hundred bucks and be FAR more trouble-free than the dual voltage Neihoff (which will cost you $3-6K from a surplus scalper...sometimes for a used takeoff). There are some other "dual voltage" solutions out there but they are crazy expensive, have really sh**y reviews, and not worth the time to even research. And a couple folks have actually installed two alts (like on ambulances) but always beware how much weight you hang off a bracket bolted to some random engine part.

These are technically 24v trucks. The 12v stuff is mostly superfulaous. Get a 24v alt and a step down when/if your alt ever fails. Until then, I wouldn't worry.

Ronmar

Well-known member

- 4,112

- 7,918

- 113

- Location

- Port angeles wa

Unless you are parking in Siberia during the winter, you don’t need that much battery(four 6t/two8D). A pair of the 6TL, or a pair of group 27 or 31s are plenty of power for the engine, and are a much better match for the 100A alt…

If you properly size the battery bank, the 100A should run you a good long time. If it does fail, I would do what Third from Texas suggests, go straight 24V and use a converter…

If you properly size the battery bank, the 100A should run you a good long time. If it does fail, I would do what Third from Texas suggests, go straight 24V and use a converter…

Last edited:

- 112,418members

- 166,094threads

- 2,339,250posts

- 792online users