They may not be easy to kill, but they do appear to have a fairly high failure rate

IRT your battery voltages, they are OK, but they also illustrate one of the biggest issues with the LMTV. Depending on the battery type those resting voltages indicate a range of 70-85% state of charge. You are not running the vehicle enough to fully charge the batteries, and the small 12v vampire load that slowly siphons away power on the outer pair of batteries Is evident by the lower voltage there. The 6TL, 4 battery bank is grossly oversized for the 100A alt. Even more so if they are AGM’s(they want nearly twice the charge current of normal wet cells). The large size means they take a long time to charge, so unless you run a lot, they just never make it. this also means the alt is running at full load most of the time you are running. Your running voltages being .1-.2v low possibly indicate this to me Also(Should be 14.1/28.2V).

Low state of charge is the largest killer of batteries there is. Failing batteries keep the alt in a constant state of overload…

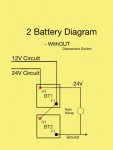

Do yourself and that $2500 alternator a favor and drop to 2 batteries(one inner and one outer). That will get you a lot closer to a good alt/battery relationship. Cat specced a pair of group 31 batteries for these engines…

Add a maintenance charger and a small battery balancer to keep the batteries nearer 100% SOC and they will last a lot longer…

Good Luck!