Gardy458

New member

- 2

- 3

- 3

- Location

- Cheyenne, Wyoming

First time posting but I've been lurking here for a while. I've had my 1952 for just over 2 years now. done quite a bit on it so far but since it was running and driving when i got it i have tried to keep from doing anything that would take it off the road for too long.

I'm finally to the point i think where i need to do some major work. First on deck is the wiring. when i bought the truck about the only wiring that worked was the charging and ignition. The lights were all either disconnected or spliced with wire nuts and all wire tags missing. I have since removed all lights and restored them, and am beginning to think about replacing all of the wiring.

Over the last week i have began tracing the wires and attempting to label everything before I pull the harness out to make a new one. it appears there were some dyslexic fellas working on this thing in the past. Im finding turn signals wired to the wrong side, and different front to back, lots of extra wires that don't seem to go anywhere even though appear to be part of the original harness, and random connectors that appear to be original but don't appear on any diagrams as well.

I think i will start this thread as not only a place to ask help from those that have more experience with these than i do, but also to share the progress and any information and resources I come up with.

A few questions I have right off the batt. What wire would you go with? Even though it wouldn't be "original" I was considering using the 14 ga Prestolite wire available from several sources, and stay away from the cloth stuff.

Second, does anyone have any pictures of them building new harnesses or harnesses laid out that they could share that i can use for reference.

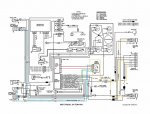

Third, I have modified the trucks schematic to be correct for the solid state flasher that is installed, anyone with a schematic savvy mind care to check my work, ill attach it below.

I'm finally to the point i think where i need to do some major work. First on deck is the wiring. when i bought the truck about the only wiring that worked was the charging and ignition. The lights were all either disconnected or spliced with wire nuts and all wire tags missing. I have since removed all lights and restored them, and am beginning to think about replacing all of the wiring.

Over the last week i have began tracing the wires and attempting to label everything before I pull the harness out to make a new one. it appears there were some dyslexic fellas working on this thing in the past. Im finding turn signals wired to the wrong side, and different front to back, lots of extra wires that don't seem to go anywhere even though appear to be part of the original harness, and random connectors that appear to be original but don't appear on any diagrams as well.

I think i will start this thread as not only a place to ask help from those that have more experience with these than i do, but also to share the progress and any information and resources I come up with.

A few questions I have right off the batt. What wire would you go with? Even though it wouldn't be "original" I was considering using the 14 ga Prestolite wire available from several sources, and stay away from the cloth stuff.

Second, does anyone have any pictures of them building new harnesses or harnesses laid out that they could share that i can use for reference.

Third, I have modified the trucks schematic to be correct for the solid state flasher that is installed, anyone with a schematic savvy mind care to check my work, ill attach it below.

Attachments

-

133.5 KB Views: 32