- 11

- 15

- 3

- Location

- Windsor, NY

Just doing some brainstorming here and thought I should start another thread. I have wanted to set up a residential cogeneration system for many years and now that I am a proud owner of an MEP-803A with only 2 hours on the clock, I feel that itch again. I suppose the robustness of the 1800 rpm design with a good quality 4 cylinder diesel and noticing all the heat discharged from the radiator section on a cool day, while load testing at 10 kw got me thinking again.

I remember reading some documentation years ago about a rule of thirds for reciprocating diesel engines referring to the fuel consumed and where that energy goes. 1/3 to produce rotational energy, 1/3 heat from the cooling system, and 1/3 heat out the exhaust.

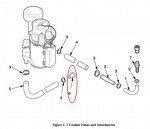

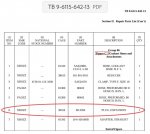

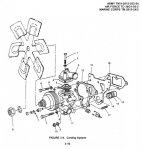

For example while producing 10 kilowatts continuously with the MEP-803A, you are consuming approximately .9 gal per hour. If 1.0 gallon of #2 diesel fuel produces approximately 138,700 Btu of heat., then .9 gal of #2 diesel would be approximately 124,830 btu. 124,830 divided by 3 = 41,610 btu. That would mean 41,610 btu generating electricity, 41,610 btu being expelled from the radiator and 41,610 btu of heat leaving in the exhaust. 10,000 watts represents approximately 34,121 btu so accounting for engine, generator, fan, alternator, water pump, etc I can see only getting 34,121 btu from the available 41,610 btu of energy (being 1/3 total). Keeping with that mindset with a 10 kw load, we should be able to easily extract some very usable heat from the cooling system and exhaust. I’m thinking at least 34,000 to 40,000 btu of heat from the cooling system and another 34,000 to 40,000 btu of heat from the exhaust. Here in upstate NY where we seem to heat 8 months out of the year, taking advantage of this waste heat makes a lot of sense. I have some ideas to integrate this into our own hydronic heating system and will be doing some real world testing to see how much heat can be obtained. My plan is to connect into the engine cooling system very similar to how the diesel fueled coolant heaters (pre heaters) are connected, or some other configuration on the engine side of the radiator thermostat. One important aspect is to maintain the coolant temperature at a level just below where the radiator thermostat opens. Since the 802’s and 803’s use a 180F thermostat, I plan to use a thermostatic mixing valve and a heat exchanger to prevent over cooling the engine cooling system. The last thing I want to do is extract so much heat the engine runs cold all the time. Plan is to leave the factory radiator and thermostat in place so excessive heat can be dumped to the atmosphere like normal. One of my first tests will be to heat a known quantity of water a certain number of degrees F and calculate how many BTUs have been extracted from the engine to do that. Additional testing will be done to find a practical and cost effective way to extract heat from the exhaust. Of course this all will depend on time and cash flow, and it seems anymore both are a challenge. If anyone has done any experimenting with extracting heat from the 802 or 803 please share here.

I remember reading some documentation years ago about a rule of thirds for reciprocating diesel engines referring to the fuel consumed and where that energy goes. 1/3 to produce rotational energy, 1/3 heat from the cooling system, and 1/3 heat out the exhaust.

For example while producing 10 kilowatts continuously with the MEP-803A, you are consuming approximately .9 gal per hour. If 1.0 gallon of #2 diesel fuel produces approximately 138,700 Btu of heat., then .9 gal of #2 diesel would be approximately 124,830 btu. 124,830 divided by 3 = 41,610 btu. That would mean 41,610 btu generating electricity, 41,610 btu being expelled from the radiator and 41,610 btu of heat leaving in the exhaust. 10,000 watts represents approximately 34,121 btu so accounting for engine, generator, fan, alternator, water pump, etc I can see only getting 34,121 btu from the available 41,610 btu of energy (being 1/3 total). Keeping with that mindset with a 10 kw load, we should be able to easily extract some very usable heat from the cooling system and exhaust. I’m thinking at least 34,000 to 40,000 btu of heat from the cooling system and another 34,000 to 40,000 btu of heat from the exhaust. Here in upstate NY where we seem to heat 8 months out of the year, taking advantage of this waste heat makes a lot of sense. I have some ideas to integrate this into our own hydronic heating system and will be doing some real world testing to see how much heat can be obtained. My plan is to connect into the engine cooling system very similar to how the diesel fueled coolant heaters (pre heaters) are connected, or some other configuration on the engine side of the radiator thermostat. One important aspect is to maintain the coolant temperature at a level just below where the radiator thermostat opens. Since the 802’s and 803’s use a 180F thermostat, I plan to use a thermostatic mixing valve and a heat exchanger to prevent over cooling the engine cooling system. The last thing I want to do is extract so much heat the engine runs cold all the time. Plan is to leave the factory radiator and thermostat in place so excessive heat can be dumped to the atmosphere like normal. One of my first tests will be to heat a known quantity of water a certain number of degrees F and calculate how many BTUs have been extracted from the engine to do that. Additional testing will be done to find a practical and cost effective way to extract heat from the exhaust. Of course this all will depend on time and cash flow, and it seems anymore both are a challenge. If anyone has done any experimenting with extracting heat from the 802 or 803 please share here.

Last edited: