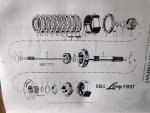

I'm going to show you a few "tricks" I was taught when I was an apprentice working on these transmissions.

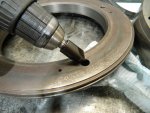

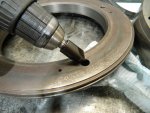

The 2 pistons in the reduction unit move on 4 "rods" which lock them to the housing. When your installing them with new seals it can be really frustrating trying to align them up with these rods. If you put a chamfer on them using a two or three flute reamer it makes it easier to get them started.

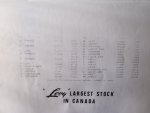

Another trick or really, a good general rebuild practice is to remove "all" the sealed off passage plugs.

Especially if your transmission experienced a major failure. Garbage can get trapped in these end-passages and later come out and play nasty with other parts. I remove all plugs and run a tap down each hole. I replaced all the plugs with stainless steel ones on this transmission.

Now this is not so much a trick as a good general practice on any rebuild of a cast iron housing. Be it an engine or transmission or transfer-case.

Flashing often happens in the casting process. This can often leave sand trapped in porous iron. You can recognize this by the way the casting looks. If not removed, you can potentially have sand come out and ruin things. Especially after cleaning up a cast housing, it can loosen this flashing.

So I use a "die grinder" and carefully remove all the flashing.

This was in the oil pan.

Speaking about the oil pan. There are 2 holes which "must" be cleaned out. They are drain holes which allow coolant or oil to escape when the cooler seals leak. Basically, they are an "early warning system" letting you know you have a leak in you oil pan cooler. Also more importantly it will keep small coolant leaks from contaminating the transmission fluid which destroys friction clutch plates. Every oil pan I have taken off has these two holes plugged up. Almost everyone needed "drilling" to remove the crud.

Also speaking on the oil pans. I strongly urge everyone to sandblast the crap out of the cooler area. This space can be just disgusting with all kinds of debris and rust. This debris can then get in-between the cooler fins. HydraMatics run "Hot" so they need all the cooling they can get.

After cleaning I paint the housing with a good primer, then a good finish coat. Don't want rust reforming any time soon.

Also adding an "inline coolant filter" before the oil pan cooler really makes a huge difference in cooling ability. Let's keep those fins clear !

Just for "grins and giggles" I thought I'd show you a M5 Tank HydraMatic oil pan next to the 303M one.

Instead of the 2 drain holes the M5 pan uses 4 holes. They did not want the transmission fluid contaminated by engine coolant.