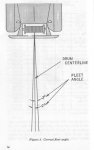

Question 1: How critical is this "fleet angle"?

Very critical, depending on which way the angle is and which way the particular layer is winding. If you're pulling towards the newer layer, much more of an angle is possible. Not exceptionally good for the cable, but if the cable is in fair to good condition and lubed at all (even if less than ideal) then you have some flexibility there. It's not good for it, but it's a lot less damaging than a lot of other things that invariably will happen to a winch cable used in this sort of application. If you're pulling away from the newest and highest layer, two degrees is great for brand spankin' new cable, but once it's settled in and trained the "grooves" between each wrap in the lower layer become less pronounced and don't trap the next layer as well, so that two degrees becomes reduced.

Example- At work, the light duty conventional wreckers, pulling in at approximately 3000 pounds (winch not straining, but cable at a full load) as the cable comes over the sheave, and onto the drum, it's lined up for the center of the drum. As the first half of a layer winds up (assuming there is a lower layer under it) that one degree is too much angle in the wrong direction, it doesn't stay tight. New cables will, old (but legally, technically and safely servicable) cables will not stay tight. They only needs a light "guide" with simple palm pressure against it to keep it tight even under that load, but once the new is gone it will not do it by it's self.The second half of every layer always stays tight by it's self.

Question 2: Is the "level wind" device and "tensioner" really needed if there is tension on the cable and the fleet angle within the 2° as shown in the FM-20-22?

I have not had the privledge of seeing a military level winder. I have used ones on our light tow trucks. If they are matched, factory options or factory retrofits, they are priceless. If they are universal, mismatched, or otherwise not perfect in every way, then not necessarily so. While the mechanics of them may be very simple, their job is quite simple. Seeing how these military ones are "supposed" to go with the winches to which they are installed, I can not see any way in which they could fail to operate correctly.

Unlike the civvy stuff I have played with, the military ones (I believe) are not tensioners, so while angle is not so much an issue, you are still not relieved of keeping tension on the cable while winding it in to keep all the wraps tight.

... Also, don't forget your ears....

I am wondering abut this myself. My winch isn't on yet, I know on civvy stuff (where you can hear yourself think when the engine is off idle) that you can hear and feel something not right with your winch and/or cable system very reliably. How much can you hear and/or feel from the deuce's driver's seat? Can you feel a cable that's rubbing something, even if it's around a corner or over an embankment, or are you relying solely on the spotter? Can you hear how much load on a cable when you've miscalculated a pull?

Has anyone found a safe way of neatly rewinding the cable after a pull?.

At work we find it's much much faster and easier to take the other approach, fix the anchor and "reel in" the tow truck up a small incline. It's heavier, that way you don't need a "big incline" which we don't have. On the wreckers it doesn't matter so much, but on the flatbets, (and I'm sure on the front winch of a deuce) you can turn the steering wheel just a touch to keep the cable always pulling just the slightest touch into the last wrap. If an operator is skilled, it is an operation that I will allow them to do themselves. New guys have to keep a skilled operator handy just in case, until they themselves demonstrate a good proficiency.

In the case of a Deuce, the winch controls are inside the cab, so a spotter would bein order, or several "stop and checks" along the way, but it would keep your hands off of the cable and keep the winch out of "auto pilot mode", both of which I would be POSSIBLY considered necessary evils, but both are definately better avoided.

This leads to proper lubrication as I see it, how do you guys handle that little detail?

New engine oil. If it's tightly wrapped, with a little practice you can pretty much gauge by how dry it looks just how much oil you can put on them. It stays OK, not as well as properl cable lube, but it's one less thing to keep around. Cable lube is tacky and gets on everything after bit. It also catches more dirt if the cable is on the ground for any reason. Engine oil is much easier to wash off of steering wheels, seats, door latches, etc. and doesn't hold dirt so much. In our business it's an easy call, since some of those dirty items may be on a customer's car. And dirt on the cable of course is abrasive, and just not a good thing at all. On a MV where the use will be minimal... How clean can you keep yourself? Can you always guarantee enough pairs of gloves to be around that you don't track cable lube all over your tool box and everything in it? Can you keep the cable off of the ground? That's the benefit and the drawback of cable lube over other lubes. It is sticky.