dmetalmiki

Well-known member

- 5,523

- 2,028

- 113

- Location

- London England

Alligning

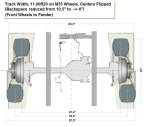

this is how we alligned them before welding and the M45 fire engine with small 900s and one pair 1200s fitted (mod) ((these have M818 spacers to allow gap between tyres)) and spacers to prevent chassis rub.

this is how we alligned them before welding and the M45 fire engine with small 900s and one pair 1200s fitted (mod) ((these have M818 spacers to allow gap between tyres)) and spacers to prevent chassis rub.

Attachments

-

19.7 KB Views: 117

-

72.9 KB Views: 210