hairba11

New member

- 66

- 0

- 0

- Location

- st. louis (high ridge)

didn't know if this was the best place to start this or not, Mods can move it if needed.

getting tired of changing headlights in the m-818, and didn't want to spend $$$ on production LED headlights so i decided to try making my own.

First step was cutting the back off one of the burnt out headlights.

I used duct tape and taped it into a 6" plumbing cap to hold it level,

then duct taped a couple of pieces of 2x4 under the angle grinder to get it the right height.

using an 1/8" cutoff wheel I was able to cut the reflector away from the lens.

it took a little work to clean up the edges. I was wearing gloves, and a dust mask, and goggles, and a full face shield to try and keep glass dust away.

the edge that was left was roughly 6" in diameter.

I used a compass with two sharp ends to scratch a 6" circle on some 1/4" plexiglass.

Putting a jigsaw upside down in the bench vise allowed me to control the material with both hands and get a fairly accurate circle cut.

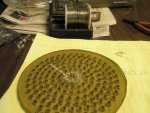

Using a rotary table and a tilt bed in the drill press I got to drilling a bunch of holes.

figuring that LED's have about a 20* viewing angle, and that headlight beams are closer to 30-35*, i drilled the first row around the outside with a 10* angle, and 10* separation on the rotary table. the next row was 5* angle, the third row will be the high beams, and they have a 7.5* angle to them. fourth row is a 2.5* angle, and the rest are flat.

when I got done I had swiss cheesed the piece of plexi.

I had already ordered a bunch of LED's and resistors off the bay, and I started installing them with Shoe Goo.

using an online LED calculator, and figuring on a max voltage of 27, I am putting a series of 7 LED and a 180 Ohm 1/2 Watt resistor together. These 7 LED strings will hopefully hold up through any voltage spikes, the truck normally runs at about 25.5v to 26v.

a little more done

Here's an idea of what it will kinda look like when I get done.

Now I'm just out of LED's and waiting for more to come in so I can finish up this light.

Then I have the joy of doing it all over again for the second if it works the way i'm hoping.

Thanks.

getting tired of changing headlights in the m-818, and didn't want to spend $$$ on production LED headlights so i decided to try making my own.

First step was cutting the back off one of the burnt out headlights.

I used duct tape and taped it into a 6" plumbing cap to hold it level,

then duct taped a couple of pieces of 2x4 under the angle grinder to get it the right height.

using an 1/8" cutoff wheel I was able to cut the reflector away from the lens.

it took a little work to clean up the edges. I was wearing gloves, and a dust mask, and goggles, and a full face shield to try and keep glass dust away.

the edge that was left was roughly 6" in diameter.

I used a compass with two sharp ends to scratch a 6" circle on some 1/4" plexiglass.

Putting a jigsaw upside down in the bench vise allowed me to control the material with both hands and get a fairly accurate circle cut.

Using a rotary table and a tilt bed in the drill press I got to drilling a bunch of holes.

figuring that LED's have about a 20* viewing angle, and that headlight beams are closer to 30-35*, i drilled the first row around the outside with a 10* angle, and 10* separation on the rotary table. the next row was 5* angle, the third row will be the high beams, and they have a 7.5* angle to them. fourth row is a 2.5* angle, and the rest are flat.

when I got done I had swiss cheesed the piece of plexi.

I had already ordered a bunch of LED's and resistors off the bay, and I started installing them with Shoe Goo.

using an online LED calculator, and figuring on a max voltage of 27, I am putting a series of 7 LED and a 180 Ohm 1/2 Watt resistor together. These 7 LED strings will hopefully hold up through any voltage spikes, the truck normally runs at about 25.5v to 26v.

a little more done

Here's an idea of what it will kinda look like when I get done.

Now I'm just out of LED's and waiting for more to come in so I can finish up this light.

Then I have the joy of doing it all over again for the second if it works the way i'm hoping.

Thanks.