- 14,639

- 4,815

- 113

- Location

- Buchanan, GA

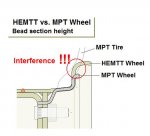

I picked up a set of recentered hemtt wheels from KBarrell this week and installed my XML's on them. Just wanted to give everyone pics and a step by step on how it's done. The workmanship of the wheels is excellent. Thick beefy center plates and great welding.

To get started, I laid down an old sheet of plywood to work on. Getting trash in the beads will only make things harder on you. Plus with all the rain, my yard was mud and muck.

I sat the wheel down in the center of my "work area". Then removed the outer ring. Kevin supplied me with some valve stems that work fine, but need a slight tweak. The ball mount on the bumper proved to be an excellent tool to tweak it. You can see in the next pic the difference between the two. This allows the stem to exit the middle of the hole for the valve stem.

The valve stem hardware is nice brass fittings as well. The side with the gasket goes inside the rim. That will force the air to seal the fitting shut. Another nice thing about the hemtt wheel vs. an A3 wheel is that this is recessed. The A3 wheel actually pokes out inside the wheel and causes the bead to snag. When installing the nut, make sure the beveled side goes inward. This centers the nut and stem assembly.

To be continued...

To get started, I laid down an old sheet of plywood to work on. Getting trash in the beads will only make things harder on you. Plus with all the rain, my yard was mud and muck.

I sat the wheel down in the center of my "work area". Then removed the outer ring. Kevin supplied me with some valve stems that work fine, but need a slight tweak. The ball mount on the bumper proved to be an excellent tool to tweak it. You can see in the next pic the difference between the two. This allows the stem to exit the middle of the hole for the valve stem.

The valve stem hardware is nice brass fittings as well. The side with the gasket goes inside the rim. That will force the air to seal the fitting shut. Another nice thing about the hemtt wheel vs. an A3 wheel is that this is recessed. The A3 wheel actually pokes out inside the wheel and causes the bead to snag. When installing the nut, make sure the beveled side goes inward. This centers the nut and stem assembly.

To be continued...

Attachments

-

56.8 KB Views: 438

-

56.2 KB Views: 409

-

80.3 KB Views: 411

-

81.3 KB Views: 408

-

36.5 KB Views: 372

-

53.4 KB Views: 360

-

53.2 KB Views: 341

-

37.6 KB Views: 338

-

36.7 KB Views: 328

-

54.5 KB Views: 430

please tell me what mpt means

please tell me what mpt means