I know there is a lot of opinions out there about recentering HMMWV wheels to get cheap double beadlocks with backspacing that works on most applications.

So about 2.5 years ago I recentered a set of 12 bolt wheels to run on my rig. I wanted about 4.75” backspacing so flat centers were the only option. I settled on a set of centers that used gussets to stiffen the wheel. The seller of the centers had even modeled it in Solidworks and had a neat color keyed stress model of it. It showed that the gussets were carrying quite a bit of load. Seemed like an elegant solution and something that would get me the backspacing I wanted.

I check wheels on everything I drive, I have seen steel wheels on a Nissan minivan crack, and total wheel shell failure on a late 2000’s Ford Expedition.

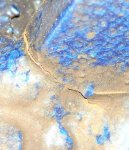

So this summer I notice that I am actually breaking the gussets above the weld on my recentered wheels. The cracks were only on the front wheels. No radical death defying failure, but failure nonetheless. So the wheels I poured a bunch of time into are scrap.

I just wanted to share just in case anyone else is running flat centers. This being said I have a buddy running stamped centers and they have been great. I think the difference with the stamped ones is that the center itself is much more rigid and there are no stress risers where they weld to the shell like the gussets on the flat centers.

The plan now is to destroy the old wheels and run bone stock grouped 24 bolt HMMWV wheels on 2” steel Stahl bolt on spacers like what is used on the front of a Ford dually pickup.

pics...

So about 2.5 years ago I recentered a set of 12 bolt wheels to run on my rig. I wanted about 4.75” backspacing so flat centers were the only option. I settled on a set of centers that used gussets to stiffen the wheel. The seller of the centers had even modeled it in Solidworks and had a neat color keyed stress model of it. It showed that the gussets were carrying quite a bit of load. Seemed like an elegant solution and something that would get me the backspacing I wanted.

I check wheels on everything I drive, I have seen steel wheels on a Nissan minivan crack, and total wheel shell failure on a late 2000’s Ford Expedition.

So this summer I notice that I am actually breaking the gussets above the weld on my recentered wheels. The cracks were only on the front wheels. No radical death defying failure, but failure nonetheless. So the wheels I poured a bunch of time into are scrap.

I just wanted to share just in case anyone else is running flat centers. This being said I have a buddy running stamped centers and they have been great. I think the difference with the stamped ones is that the center itself is much more rigid and there are no stress risers where they weld to the shell like the gussets on the flat centers.

The plan now is to destroy the old wheels and run bone stock grouped 24 bolt HMMWV wheels on 2” steel Stahl bolt on spacers like what is used on the front of a Ford dually pickup.

pics...

Attachments

-

69.8 KB Views: 51

-

60.2 KB Views: 53