rustystud

Well-known member

- 9,361

- 3,257

- 113

- Location

- Woodinville, Washington

Don't bother with money for freight. It didn't cost much. Just enjoy your new servo.I did, Ill send you a check for freight, thank you

Steel Soldiers now has a few new forums, read more about it at: New Munitions Forums!

Don't bother with money for freight. It didn't cost much. Just enjoy your new servo.I did, Ill send you a check for freight, thank you

That 1" bright spot was the only thing still holding this part together.

That 1" bright spot was the only thing still holding this part together.

Are you buying another truck ?Great work Studly.. This is truly a fantastic thread. You may have another transmission coming your way....

Great !!!Yep, it's coming to the shop. Wifey agreed to the deal..because I'm her favorite...and it's just around the bend from me. Practically followed me home.

I have yet to see it in person. I'm hoping to get home next week and do an evaluation of the power pak. My 135 and this 211 are both slated for repowers. This one I'm thinking will get a 4-71 and 13 over road ranger. keep the tcase single speed and use the pto for a hiab i picked up today. The 135 is going to get the 2 speed converted tcase. The 303 I'll save for you.

No automatic transmission was ever designed to use 30W oil, including the HydraMatic. GMC just gave the military a "waiver" on using 30W oil since the military mechanics didn't know what to do with an automatic. Plus, it was one less oil the military didn't need to stock up on.Not to change the subject matter. The original transmission were designed to run on 30wt oil. Did you start using atf or stay with the 30wt. ?? I haven’t had that series truck for about 10 years. I really liked that truck for the auto trans. The M135 I had would cruise at 65 on flat ground until the tires would start to bounce. Wouldn’t climb hills for crap.but no military truck does. It looks like it had atf in it. Just asking.

You see that ring in the case ? That was from the front clutch assembly grinding into it. It was almost through the metal.

You see that ring in the case ? That was from the front clutch assembly grinding into it. It was almost through the metal.

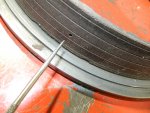

This oil delivery sleeve has the seal ring welded in ! I have never seen such heat related damage !

This oil delivery sleeve has the seal ring welded in ! I have never seen such heat related damage ! Besides having that groove cut into the housing, the rust damage was extensive in the main case.

Besides having that groove cut into the housing, the rust damage was extensive in the main case. The front clutch assembly had welded itself together. I didn't even try to disassemble it.

The front clutch assembly had welded itself together. I didn't even try to disassemble it. The gears had seized on this shaft.

The gears had seized on this shaft.

You apply air pressure here to apply the "reduction" piston. Be very careful to "NOT" use too much air pressure here. 20 Ibs of air pressure is all you need to check the seals. Just allow the piston to gently rise up about 3/16" no more, since the "driven cone" has no "stationary cone" to push against it yet. Without the "stationary cone" the piston can blow out of its bore.

You apply air pressure here to apply the "reduction" piston. Be very careful to "NOT" use too much air pressure here. 20 Ibs of air pressure is all you need to check the seals. Just allow the piston to gently rise up about 3/16" no more, since the "driven cone" has no "stationary cone" to push against it yet. Without the "stationary cone" the piston can blow out of its bore.

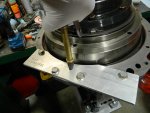

The test plate needs to cover this "T" shaped hole shown here.

The test plate needs to cover this "T" shaped hole shown here.I'm a huge fan of nordlocks..Rolls Royce marine junk used that design before nordlock was a thing. Hugely effective and non marring for the most part.Today I'll show you how to check the "reduction" piston and the "direct clutch" piston.

I finally received the new reduction pistons outer oil seals from "Fatsco" . I bought two. They have six left.

So, I reassembled the reduction unit (again !) and now I need to check the operation of the pistons.

Just a note here: I would recommend using "NordLocks" on the bolts since the "straps" are no longer available and the old straps are all worn out and are basically useless to prevent the bolts from loosening.

View attachment 935914

View attachment 935919 You apply air pressure here to apply the "reduction" piston. Be very careful to "NOT" use too much air pressure here. 20 Ibs of air pressure is all you need to check the seals. Just allow the piston to gently rise up about 3/16" no more, since the "driven cone" has no "stationary cone" to push against it yet. Without the "stationary cone" the piston can blow out of its bore.

View attachment 935915View attachment 935916View attachment 935917

I made up a "test plate" to air test the "direct clutch" piston.

View attachment 935918

View attachment 935920 The test plate needs to cover this "T" shaped hole shown here.

You can use full air pressure here once you bolt down and torque the bolts for the "internal gear assembly" to the "reduction clutch drum". The bolts I used the "NordLocks" on.

On either piston, you should have no leakage at all. If you do, disassemble it and find out why it's leaking. Usually it's because you allowed the oil seal to twist in it's bore.

When I was installing the reduction piston, one side was not going down. The oil seal had come partially out of the bore. So, I added more assembly lube and pushed the seal back in. The assembly lube helps hold in the seals.

Remember when installing the large reduction piston to "never" push hard to install it. It should almost go in all by itself if done correctly. Once it has started going into its bore (about a 1/4" ) you can gently push it in the rest of the way.

It'll be nice to see you. I'm going to have a little time to myself in december. Hopefully the weather will co operate and i can make some hay. Word on the street at the drydock is Jan and Feb will be mayhem. 6 vessels with 5 year major overhauls in 2-2 1/2 months. All mechanical. No time to even sleep. I'll keep you posted.Great !!!

Thanks Duuane.

It will be nice to see your new place.

Yes. Every 303M I have torn down was missing this bushing.On this latest tear down, was it also missing the bushings that all the previous ones were?

Yes, I've been a fan of NordLocks for decades now. Their expensive, but worth every penny !i

I'm a huge fan of nordlocks..Rolls Royce marine junk used that design before nordlock was a thing. Hugely effective and non marring for the most part.