I'm still tearing down one of the transmissions I picked up in Canada. Today I found out the cause of death for this transmission. Water. Seems the last owner took his M135 for a swim.

There was extensive damage to many different parts of the transmission. The reduction units clutches where severely worn. The front and rear clutch packs were destroyed. Literally ! The front pumps vanes were totally worn out. The rear pump had damage. The reverse piston had so much heat the lip seal melted, and the cast iron piston cracked in three places. So many areas had damage.

So today I was inspecting the front clutches more closely and found the friction plates were shedding their paper material. The only thing that can cause this is water.

I'm sure your asking how could water cause high heat in the reverse piston and extreme wear in the front and rear pumps. Well water is a terrible lubricant for metal parts and will destroy a pump used to pressurize oil. Since it had no oil to pump to the system just water, all those parts needing lubrication had nothing and overheated.

Now whoever did this tried to drain the water and add back transmission fluid, but it was too late. Probably drove it back home after taking a swim. When I was still in the "Marine's Motor Pool" we were taught that you immediately drained all fluids after taking a swim with a Deuce or any equipment really. The only time you were allowed to drive any distance was in a "combat" situation. Then you just drove it until it died.

So for you crazy guys who love to take your vehicles out and play hard with them, take notice here. Automatic transmission vehicles will get destroyed from water.

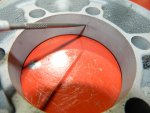

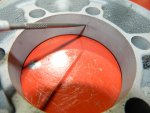

Here you can see the melted seal.

There is melted rubber on the housing. It's the black spot at the top.

Here you can see the three cracks in the piston. I cleaned up the piston and then found the cracks. The piston was black from baked on oil.

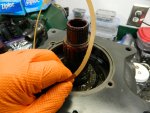

You can see the wear on the pump vanes from the alignment rings.

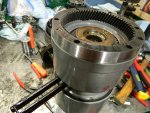

I've never seen this before. A bronze selective thrustwasher broken like this.

There must have been some nasty hammering of the input shaft to cause this. That combined with the lack of oil totally destroyed this washer.

This poor transmission died a terrible death !

Using the special clamp tool again I compress the seal rings and install the rear drum assembly.

Using the special clamp tool again I compress the seal rings and install the rear drum assembly.

This hole applies the front clutch.

This hole applies the front clutch. This hole applies the rear clutch.

This hole applies the rear clutch.