deuceman51

Member

- 885

- 10

- 18

- Location

- Scotland South Dakota

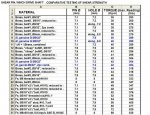

I have read the threads on the shear pins with the tests etc. I have a winch that the previous owner drilled to 5/16 so the correct 9/32 is out of the question. I can't seem to find the shearing psi rating for 2024-T361 Al to compare it to the GI 44-45,000Psi rating. Does anybody have a online source where I can find out where the 5/16 2024-T361 compares? I tried google, but didn't come up with much. I'm planning on ordering the 5/16 Al to make my own pins, but would like to know just how much difference 1/32 of an inch is going to make on the psi before we grenade a winch.

Thanks in advance.

Thanks in advance.