When I assemble an engine I like to coat the bearings and piston skirts with assembly lube. Gives a little extra protection at start up. I usually just wipe a thin coat of oil on the rings. No assembly lube on those.

-

Steel Soldiers now has a few new forums, read more about it at: New Munitions Forums!

803 Bogs Down and dies at 85% Load

- Thread starter USAMilRet

- Start date

More options

Who Replied?USAMilRet

Member

- 390

- 15

- 18

- Location

- Tampa, Florida

I have used this method to put bearings, gears and such things on pumps. Normally they go right on without much trouble.

Worked like a charm. Got the oven to 460 and let the gear sit in the oven for about 30 minutes to heat up. Put it on the crankshaft and it slid a bit into place and I used a large socket (for the Motor Home) and tapped it into place. Just a tiny tap here and there.We use a bearing heater here at work. After you get it to the proper degree it will slid on by hand. If you start to put it on and it sticks knock it back off and heat more.

USAMilRet

Member

- 390

- 15

- 18

- Location

- Tampa, Florida

I always use an assembly lube on my rebuilds. I can not tell you how many engines that I have heard about being destroyed by a dry start up. Yep, that metal to metal with no lube is just screeching to be released.When I assemble an engine I like to coat the bearings and piston skirts with assembly lube. Gives a little extra protection at start up. I usually just wipe a thin coat of oil on the rings. No assembly lube on those.

USAMilRet

Member

- 390

- 15

- 18

- Location

- Tampa, Florida

Got the pistons installed with no issues except the rings. I noticed that if you are not very careful when using the ring compressor that you can spin the ring out of position. Have to be very careful about that or else you can wind up with on ring split sitting right on top of another one.

The camshaft did not want to go inside the camshaft bearing. The split in the bearing was at the top but was completely closed and sure enough, it made the bearing .001in smaller than the diameter of the camshaft journals. PITA to get out but I used the old bearing (from the last rebuild 15.5 hours ago) as it was just as new and in specs as required by the TM. I hated to do it but if I did not, I would be down for another week.

Tried installing a new relief valve in the oil pump that I got from HQ Motors just to find out that it would not thread into the oil pump. Spent 1/2 hour trying to figure out what the issue was. The old one went in just fine, the spare I got went in just fine, but the new one from HQ would not thread into the pump.

So bad sized bearing and a problem with the new relief valve. Neither a show stopper.

Bottom half is put together so tomorrow it will be the top half.

The camshaft did not want to go inside the camshaft bearing. The split in the bearing was at the top but was completely closed and sure enough, it made the bearing .001in smaller than the diameter of the camshaft journals. PITA to get out but I used the old bearing (from the last rebuild 15.5 hours ago) as it was just as new and in specs as required by the TM. I hated to do it but if I did not, I would be down for another week.

Tried installing a new relief valve in the oil pump that I got from HQ Motors just to find out that it would not thread into the oil pump. Spent 1/2 hour trying to figure out what the issue was. The old one went in just fine, the spare I got went in just fine, but the new one from HQ would not thread into the pump.

So bad sized bearing and a problem with the new relief valve. Neither a show stopper.

Bottom half is put together so tomorrow it will be the top half.

Cam bearings often have to be align bored/honed after install. Not an at home task.Got the pistons installed with no issues except the rings. I noticed that if you are not very careful when using the ring compressor that you can spin the ring out of position. Have to be very careful about that or else you can wind up with on ring split sitting right on top of another one.

The camshaft did not want to go inside the camshaft bearing. The split in the bearing was at the top but was completely closed and sure enough, it made the bearing .001in smaller than the diameter of the camshaft journals. PITA to get out but I used the old bearing (from the last rebuild 15.5 hours ago) as it was just as new and in specs as required by the TM. I hated to do it but if I did not, I would be down for another week.

Tried installing a new relief valve in the oil pump that I got from HQ Motors just to find out that it would not thread into the oil pump. Spent 1/2 hour trying to figure out what the issue was. The old one went in just fine, the spare I got went in just fine, but the new one from HQ would not thread into the pump.

So bad sized bearing and a problem with the new relief valve. Neither a show stopper.

Bottom half is put together so tomorrow it will be the top half.

USAMilRet

Member

- 390

- 15

- 18

- Location

- Tampa, Florida

Well, I finally have the engine put back together. Spent a week on vacation so I got delayed. I also had to wait on parts from the seller which for some reason took a month to get. It is married to the generator and in the cabinet. I will finish doing the install today and will try to fire it up after filters and fluids.Cam bearings often have to be align bored/honed after install. Not an at home task.

What are the rebuilt engine restart processess? I have read to crank for 15 to 20 sec for oil flow and lifter oil charging. Start engine and run to operating temp checking for leaks. Place a load on engine according to TM and run for break in.

Any other recommendations?

- 2,586

- 2,290

- 113

- Location

- Efland, NC

That sounds like what I would do.

USAMilRet

Member

- 390

- 15

- 18

- Location

- Tampa, Florida

So I got it started today. Still having issues with the stop fuel solenoid. This is a new solenoid and it will not retract the lever but will hold the levrt in place if I push the rod to the full interior. Will have to trace the circuit and see if there is a voltage bleed on the lines.

Ran it for an hour in 3 phase loaded to 95% indicated and 31 amps on each leg. Hummed right along but the engine just sounds strange to me. Maybe it is because it is newly rebuilt. Smoking at 95% indicated but as expected until rings set.

Will have to test at 240VAC to see if I can get over 100% indicated.

Almost completely assembled. Those new batteries, the SL22NF seem to be able to drive the motor no problems. Battery says 330 CCA and that's fine for FL. Cost was about $68 new and they are almost identical in size to the 51R.

Ran it for an hour in 3 phase loaded to 95% indicated and 31 amps on each leg. Hummed right along but the engine just sounds strange to me. Maybe it is because it is newly rebuilt. Smoking at 95% indicated but as expected until rings set.

Will have to test at 240VAC to see if I can get over 100% indicated.

Almost completely assembled. Those new batteries, the SL22NF seem to be able to drive the motor no problems. Battery says 330 CCA and that's fine for FL. Cost was about $68 new and they are almost identical in size to the 51R.

Last edited:

LonestarFisher

New member

- 9

- 1

- 3

- Location

- Beaufort, TX

Whew! I opened this thread thinking I could offer some engine input but man you guys got it covered! USAMilRet, great pictures and info! I'm sure this will help others with their rebuilds in the future. I came here looking for truck info but all of this equipment is so enticing!

I feel like I can still offer some advice though. You mentioned you were going to release the name of the vendor you purchased this from when you were done. I don't recommend that. There are 40 pages of criticism on a public forum here. The vendor could sue for slander... trust me. It happened to me. I used to run a small wholesale fish business in the Gulf and one of my competing companies was doing some real shady stuff and their customer started buying from me. They would mention this when we talked and I would agree, these practices were unethical and possibly illegal. Well, he caught wind of it and sued me for slander. he wanted small-claims max which is $10,000. MY attorney told me to settle because the cost to litigate would far exceed that if we went to trial, even though he was 100% certain I would win.

We ended up settling on $4000 plus my attorneys fees which ran about $7500. The real kicker... he didn't even have a lawyer. His total out of pocket expense was $34 to file. I did nothing wrong yet I got sued and LOST because winning was too expensive.

We live in a sue-happy world now. My advice, keep it to yourself and just recommend everyone exercise "caveat emptor". "Buyer beware". With the exposure the internet has, if the vendor can articulate a loss of business, they may actually have a case... as crazy as it sounds. heck, they don't even need to have a loss of business to file and create a living nightmare for you.

Just my two cents. Been there, done that. Never again. The only person I talk bad about people now to is my wife!!

I feel like I can still offer some advice though. You mentioned you were going to release the name of the vendor you purchased this from when you were done. I don't recommend that. There are 40 pages of criticism on a public forum here. The vendor could sue for slander... trust me. It happened to me. I used to run a small wholesale fish business in the Gulf and one of my competing companies was doing some real shady stuff and their customer started buying from me. They would mention this when we talked and I would agree, these practices were unethical and possibly illegal. Well, he caught wind of it and sued me for slander. he wanted small-claims max which is $10,000. MY attorney told me to settle because the cost to litigate would far exceed that if we went to trial, even though he was 100% certain I would win.

We ended up settling on $4000 plus my attorneys fees which ran about $7500. The real kicker... he didn't even have a lawyer. His total out of pocket expense was $34 to file. I did nothing wrong yet I got sued and LOST because winning was too expensive.

We live in a sue-happy world now. My advice, keep it to yourself and just recommend everyone exercise "caveat emptor". "Buyer beware". With the exposure the internet has, if the vendor can articulate a loss of business, they may actually have a case... as crazy as it sounds. heck, they don't even need to have a loss of business to file and create a living nightmare for you.

Just my two cents. Been there, done that. Never again. The only person I talk bad about people now to is my wife!!

Last edited:

- 17,512

- 25,924

- 113

- Location

- Burgkunstadt, Germany

That's what makes this forum so good. Folks like you tell about what happened, how it worked, what you did and all that stuff. And even though I yelled loudest, I suppose it's better to not put someone's name in here for poor work. But it still rubs me wrong. A man, or woman's word should be their bond. And when it isn't, then as long as I don't lie about them, that's the way it is. Getting to old for this world I guess.

LonestarFisher

New member

- 9

- 1

- 3

- Location

- Beaufort, TX

A man, or woman's word should be their bond. And when it isn't, then as long as I don't lie about them, that's the way it is. Getting to old for this world I guess.

Couldn't have said it better myself. I didn't speak one lie. I didnt even initiate the bad talk, the customers did. I just sort of responded with things like 'um hum... well, you wont have to worry about that here'. Or, in response to 'xyz sold me this or said that'.... I'd respond with 'Yeah, I've been hearing about that lately. We'll take good care of you here'. I got slapped with that lawsuit in the late 2000's and ended up closing the business a couple years later in 2011; the Deepwater Horizon oil spill pretty much put me out of business. I had lost my nerve for it after the lawsuit anyway. Work felt like a chore and everyday I felt intimidated and afraid of average customers. It wasn't fair to me or my customers anymore.

I can remember my father sealing deals with a handshake back in the 70s. I guess even then people still had some integrity. Times certainly are different now. I wont say a bad word about anyone anymore. Mouth shut, smile on my face. If you've done me right, I'll praise you to the ends of the world. If you've done me wrong, no comment. Sad but it's the safest approach now. Good for me, not so good for those I wish to warn.

USAMilRet

Member

- 390

- 15

- 18

- Location

- Tampa, Florida

This is not thr 70s.

I am still not done yet. One of the original issues rear its head because it was never solved. The fuel solenoid still does not retract for the genset to run.

Original solenoid started to fail by not retracting but if manually retracted, it will stay engaged. Usually a case of tired soleniod.

Spent $126 + $26s/h for a new unit. Same issue, will not retract but will stay engaged if manually retracted.

Replaced solenoid with one of my new units soleniod, no function at all.

Replaced solenoid with a second one from my new units, same issue, will not retract but will stay engaged if manually retracted.

Voltage across pins 1 and 3 is 23vdc. Can not get a reading off of pins 1 and 2, and 2 and 3....not enough hands.

TMs are no help......replace.

Now ' my understanding is ' when S1 is energized to either crank or run, the solenoid should be energized across 2 pins for the rod to retract. When in run mode, pins 1 and 3 are energized to hold the rod in the solenoid while the genset is running. This leaves me to believe that pins 1 and 2 are either for the purpose of retracting the rod or is part of the emergency cut off/fault circuit.

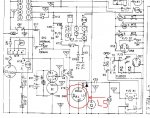

Either way, there is no juice ornot enough juice to retract the rod but there is enough juice to hold it in place if manually retracted. Schematic showe both part of thr run and strat circuit, green and blue.

I am still not done yet. One of the original issues rear its head because it was never solved. The fuel solenoid still does not retract for the genset to run.

Original solenoid started to fail by not retracting but if manually retracted, it will stay engaged. Usually a case of tired soleniod.

Spent $126 + $26s/h for a new unit. Same issue, will not retract but will stay engaged if manually retracted.

Replaced solenoid with one of my new units soleniod, no function at all.

Replaced solenoid with a second one from my new units, same issue, will not retract but will stay engaged if manually retracted.

Voltage across pins 1 and 3 is 23vdc. Can not get a reading off of pins 1 and 2, and 2 and 3....not enough hands.

TMs are no help......replace.

Now ' my understanding is ' when S1 is energized to either crank or run, the solenoid should be energized across 2 pins for the rod to retract. When in run mode, pins 1 and 3 are energized to hold the rod in the solenoid while the genset is running. This leaves me to believe that pins 1 and 2 are either for the purpose of retracting the rod or is part of the emergency cut off/fault circuit.

Either way, there is no juice ornot enough juice to retract the rod but there is enough juice to hold it in place if manually retracted. Schematic showe both part of thr run and strat circuit, green and blue.

Last edited:

justacitizen

Active member

- 408

- 40

- 28

- Location

- oklahoma

i really don't know but while i was waiting for someone who does i would make sure the solenoid ground was real good. and that the wire connections aren't weak or corroded.

USAMilRet

Member

- 390

- 15

- 18

- Location

- Tampa, Florida

Already did. The wire harness is fine.

The green start circuit energizes the pull condition on the solenoid. The blue run circuit energizes the hold condition on the solenoid. This means that the hold circuit blue is working but the pull circuit green is not.

Thats a pretty simple circuit to follow....I hope.

The green start circuit energizes the pull condition on the solenoid. The blue run circuit energizes the hold condition on the solenoid. This means that the hold circuit blue is working but the pull circuit green is not.

Thats a pretty simple circuit to follow....I hope.

USAMilRet

Member

- 390

- 15

- 18

- Location

- Tampa, Florida

Crank disconnect relay maybe?

USAMilRet

Member

- 390

- 15

- 18

- Location

- Tampa, Florida

Pulled K16 to make sure it was seated, which it was. Same issue......hold works, pull does not.

That's what I'm thinking, K16 (crank disconnect). Try swapping the Relay with another one and make sure all your connections are tight on K16. I've been searching the schematics and can not find L5 (fuel solenoid) or any wires going to L5. The only description is on the colored schematic that Guy and others put together.

- 2,262

- 3,972

- 113

- Location

- Pepperell, Massachusetts

USAMilRet

Member

- 390

- 15

- 18

- Location

- Tampa, Florida

Thats the schematic I am using, which is a copy of the schematics on the door.

If you look at the green circuit from the starter solenoid to fuel solenoid (circuled above) only the K16 is between the two terminals. Of course, it may cross 4 terminal boards, change wire number 3 times, and run 6 times around the control panel........

Me thinks I have a break in one of my wires, the starter solenoid to the fuel solenoid 'pull' function. Can't be the red or black as I get a reading across pin 1 and 3. So it's pin 2 or the white wire 100D16 which goes to the control box. On the starter side wire 178A20 is the feed voltage of 24vdc to the control box. I need a real schematic. I giess i can try the wkre harness diagrams.

If you look at the green circuit from the starter solenoid to fuel solenoid (circuled above) only the K16 is between the two terminals. Of course, it may cross 4 terminal boards, change wire number 3 times, and run 6 times around the control panel........

Me thinks I have a break in one of my wires, the starter solenoid to the fuel solenoid 'pull' function. Can't be the red or black as I get a reading across pin 1 and 3. So it's pin 2 or the white wire 100D16 which goes to the control box. On the starter side wire 178A20 is the feed voltage of 24vdc to the control box. I need a real schematic. I giess i can try the wkre harness diagrams.

- 112,609members

- 166,199threads

- 2,340,856posts

- 1,004online users