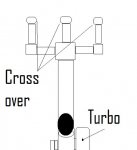

I had thought of using pbc pipe that should handle 100lbs of water pressure. It can handle hot water of about 200 degrees. What I have wondered is if it could handle being the crossover. Being pressurized, I was wondering if the right angles would be OK.yes I tried that. there is only about 2 inches between the hood and turbo discharge. I hammered the pipe nearly flat and bent the hood support out of the way and it still didn't look right and wasn't going to function very well. hence the idea of running it next to the block behind the fan.

If I used pipes to cross over in mutable places. just a thought.

Attachments

-

18.4 KB Views: 84