combat jump

Member

- 143

- 4

- 18

- Location

- Raleigh, NC

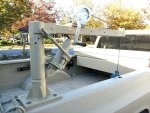

I'm putting a crane in the bed of my M1028.

I'll share some construction info as I go, in case anyone else is inspired. Here's what I am going for:

1. Low cost. Using a modified Harbor Freight truck bed crane, on a mast, with both ram for raising the boom, and a hand crank winch.

2. Braced well, not simply bolted to the floor. will have to augment the original hardware, and fab up some bracing.

3. Fairly low profile. Must look like it "belongs" to the casual observer.

4. Must be removable. I like keeping my truck looking like an original CUCV.

5. would like to lift my 550 pound motorcycle into the back of the truck with it. if I could pick up my spare 6.2L engine with it, that would be even better.

Tools on hand:

1. 4x6 horizontal bandsaw. Mine is a Jet, but its identical to the HF model.

2. Miller 211 mig

3. Miller 375 Xtreme plasma cutter (for punching bolt holes into the plate)

4. Oxy cutting torch (for the same, until I ran out of gas)

5. 4 1/2" and 7" Dewalt grinders

6. Drill press and hand held drill, plus good bits for steel

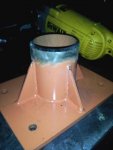

First stop was the steel yard, which also sells scrap (Sims Metals in San Jose, CA). I found some scrap 3/8" plate for a base, and bought some 1 1/5" x 1/4" for to fill the valleys of the bed floor. I have a length of 4" x 1/4" wall square steel tubing that I'll use as a mast (you'll have to wait for the pictures).

I cut the 3/8" plate into a shape that would drop into the space behind the right wheel well. Nearly up against the bed reinforcements that come with an M1028, I'll weld a tab on to brace it there.

1/2" all thread connects the 3/8" plate to a brace underneath that I fabbed from smaller square steel tubing x .120 wall.

So far, I'm off to a good start. I'll post pics as I make progress.

CJ

I'll share some construction info as I go, in case anyone else is inspired. Here's what I am going for:

1. Low cost. Using a modified Harbor Freight truck bed crane, on a mast, with both ram for raising the boom, and a hand crank winch.

2. Braced well, not simply bolted to the floor. will have to augment the original hardware, and fab up some bracing.

3. Fairly low profile. Must look like it "belongs" to the casual observer.

4. Must be removable. I like keeping my truck looking like an original CUCV.

5. would like to lift my 550 pound motorcycle into the back of the truck with it. if I could pick up my spare 6.2L engine with it, that would be even better.

Tools on hand:

1. 4x6 horizontal bandsaw. Mine is a Jet, but its identical to the HF model.

2. Miller 211 mig

3. Miller 375 Xtreme plasma cutter (for punching bolt holes into the plate)

4. Oxy cutting torch (for the same, until I ran out of gas)

5. 4 1/2" and 7" Dewalt grinders

6. Drill press and hand held drill, plus good bits for steel

First stop was the steel yard, which also sells scrap (Sims Metals in San Jose, CA). I found some scrap 3/8" plate for a base, and bought some 1 1/5" x 1/4" for to fill the valleys of the bed floor. I have a length of 4" x 1/4" wall square steel tubing that I'll use as a mast (you'll have to wait for the pictures).

I cut the 3/8" plate into a shape that would drop into the space behind the right wheel well. Nearly up against the bed reinforcements that come with an M1028, I'll weld a tab on to brace it there.

1/2" all thread connects the 3/8" plate to a brace underneath that I fabbed from smaller square steel tubing x .120 wall.

So far, I'm off to a good start. I'll post pics as I make progress.

CJ

Attachments

-

50.8 KB Views: 138

-

54.9 KB Views: 132