gimpyrobb

dumpsterlandingfromorbit!

- 27,786

- 755

- 113

- Location

- Cincy Ohio

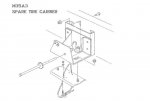

Anyone have any pics of the A3 spare tire mount? I am using an A3 rim and tire for a spare and the backset of the rim doesn't really work with my A2 spare carrier. Before I go crazy building a "Gimpyrig" I'd like to see a factory mount. TIA.