mactiredearg

New member

- 199

- 1

- 0

- Location

- Denver, Colorado

I'm looking for advice, suggestions, examples of similar work, etc. Your help is greatly appreciated.

So, I have an M109A4 with a frozen transmission. (yes I know A3s suck, I agree, moving on now...)

My issue: If the engine is running the transmission locks up, meaning the output shaft to the transfer case becomes stuck in place as if it were welded, even in neutral. The transmission actually went while I was driving and brought the truck to a complete stop faster then the brakes would have. Luckily I was on a side road at the time. Anyways, turn the engine off and the output spins freely like kid's toy top. I've checked all the usual suspects including fluids and everything is normal. But I have to admit I have not dropped the pan to see how many pieces are sitting there.

Since the transmission obviously has to come out anyways I'm looking for alternatives to spending the time, effort and money to just stick the same POS back in. Also, I know where I can lay my hands on a good A2 manual transmission.

I've searched here repeatedly and found lots of threads about how swapping out the A3's transmission is very do-able, but nothing showing it actually done. And while I can turn a wrench (keep comments to yourself SteelAndCanvas), I have no experience swapping transmissions. So I'd like to pick folks brains about the best ways to do this and if it is even possible. Help me out and if I pull it off I'll post the pictures!

First, I know any transmission can bolt to almost any engine if you use the right bell housing adaptor. The question here is once the A2 tranny is bolted to the Cat will the transmission line up with the cab correctly so that the shifter will not only be able to come through the floor, but will be usable (meaning the shifter can be moved into the various gears without running into the dash or the seats first). (kind of a deal breaker if I can't shift)

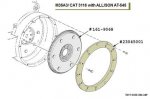

Second, from briefly talking with Cat and posts on here I believe I need an engine SAE 1 to transmission SAE 2 bell adapter. Can anyone confirm?

Third, the list of parts I can think of that I will need is: flywheel, clutch, clutch linkage, hanging pedal. I know I'm missing something, probably important, from the list. What else do I need?

Fourth, suggestions and advice. I'm reading up on the threads I can find about removing a Deuce tranny, but any and all suggestions would be greatly appreciated. I knew when I got these trucks that I was signing up for some heavy duty work eventually, just didn't expect it to be this soon.

Thank you in advance,

Brendan (aka mactiredearg)

Thread requests:

- I'm not trying to start an A2 vs A3 religious war, just trying to get my truck rolling again so my girls can enjoy it. If you have hate for the A3s please express it elsewhere (I may even join in).

- Purists, I realize I'm modifying. If the tranny hadn't broken I'd have left it. But I see no reason to rebuild a tranny that broke with less than 2k miles just so it can do it again later. Also, the motor pool guys have been known to throw whatever they had together to get something moving. So it's not out of the realm of possibility that this wouldn't be representative of their ingenuity if presented with the same issue and the same resources.

So, I have an M109A4 with a frozen transmission. (yes I know A3s suck, I agree, moving on now...)

My issue: If the engine is running the transmission locks up, meaning the output shaft to the transfer case becomes stuck in place as if it were welded, even in neutral. The transmission actually went while I was driving and brought the truck to a complete stop faster then the brakes would have. Luckily I was on a side road at the time. Anyways, turn the engine off and the output spins freely like kid's toy top. I've checked all the usual suspects including fluids and everything is normal. But I have to admit I have not dropped the pan to see how many pieces are sitting there.

Since the transmission obviously has to come out anyways I'm looking for alternatives to spending the time, effort and money to just stick the same POS back in. Also, I know where I can lay my hands on a good A2 manual transmission.

I've searched here repeatedly and found lots of threads about how swapping out the A3's transmission is very do-able, but nothing showing it actually done. And while I can turn a wrench (keep comments to yourself SteelAndCanvas), I have no experience swapping transmissions. So I'd like to pick folks brains about the best ways to do this and if it is even possible. Help me out and if I pull it off I'll post the pictures!

First, I know any transmission can bolt to almost any engine if you use the right bell housing adaptor. The question here is once the A2 tranny is bolted to the Cat will the transmission line up with the cab correctly so that the shifter will not only be able to come through the floor, but will be usable (meaning the shifter can be moved into the various gears without running into the dash or the seats first). (kind of a deal breaker if I can't shift)

Second, from briefly talking with Cat and posts on here I believe I need an engine SAE 1 to transmission SAE 2 bell adapter. Can anyone confirm?

Third, the list of parts I can think of that I will need is: flywheel, clutch, clutch linkage, hanging pedal. I know I'm missing something, probably important, from the list. What else do I need?

Fourth, suggestions and advice. I'm reading up on the threads I can find about removing a Deuce tranny, but any and all suggestions would be greatly appreciated. I knew when I got these trucks that I was signing up for some heavy duty work eventually, just didn't expect it to be this soon.

Thank you in advance,

Brendan (aka mactiredearg)

Thread requests:

- I'm not trying to start an A2 vs A3 religious war, just trying to get my truck rolling again so my girls can enjoy it. If you have hate for the A3s please express it elsewhere (I may even join in).

- Purists, I realize I'm modifying. If the tranny hadn't broken I'd have left it. But I see no reason to rebuild a tranny that broke with less than 2k miles just so it can do it again later. Also, the motor pool guys have been known to throw whatever they had together to get something moving. So it's not out of the realm of possibility that this wouldn't be representative of their ingenuity if presented with the same issue and the same resources.